For many new users, the 6090 UV printer is the core production machine in their workshop.

To ensure stable output and prevent minor issues from turning into costly repairs, our Senior technical team created this practical maintenance guide.

It explains common problems and offers a clear maintenance routine to help you extend equipment life and maximize production value.

1. Early Warning Signs: Color Missing and Ink Break Issues

If you notice missing colors, broken lines, or uneven output during printing or test strips, first check the consumable parts of the ink system.

These parts wear with use and must be replaced on schedule to maintain smooth ink flow.

Key Consumables (Recommended Replacement Cycle: Every 6–12 Months)

- Dampers

The internal filter gradually accumulates ink residue and dust, reducing ink flow.

Replacing dampers ensures stable ink delivery to the print head. - Ink Pump

The pump generates suction during cleaning.

Weak pump pressure leads to incomplete cleaning and poor waste ink discharge, which can cause nozzle clogging. - Wiper Blade

The blade wipes the print head surface during cleaning.

If damaged or aged, it causes poor cleaning and ink mixing.

Clean with UV cleaning solution only. Do not use water. - Capping Pad

Located under the capping station, it absorbs waste ink.

When saturated, waste ink may overflow or backflow, contaminating the print head.

Action Plan:

Do not wait until clogs appear.

Replace consumables every 6–12 months based on usage — this prevents 80% of print quality issues.

6090 Printer Uv flatbed

2. Foundation of Daily Stability: Guide Rail Maintenance

How to Maintain

- Clean dust and ink residue on the guide rail using a lint-free cloth.

- Apply a thin layer of UV printer solid grease.

Why It Matters

The guide rail supports the print head carriage.

Smooth motion prevents vibration, misalignment, and ghosting.

Regular lubrication protects print accuracy and reduces wear.

3. Deep Maintenance: Capping Station and Sensors

1) Capping Station — The Print Head “Home”

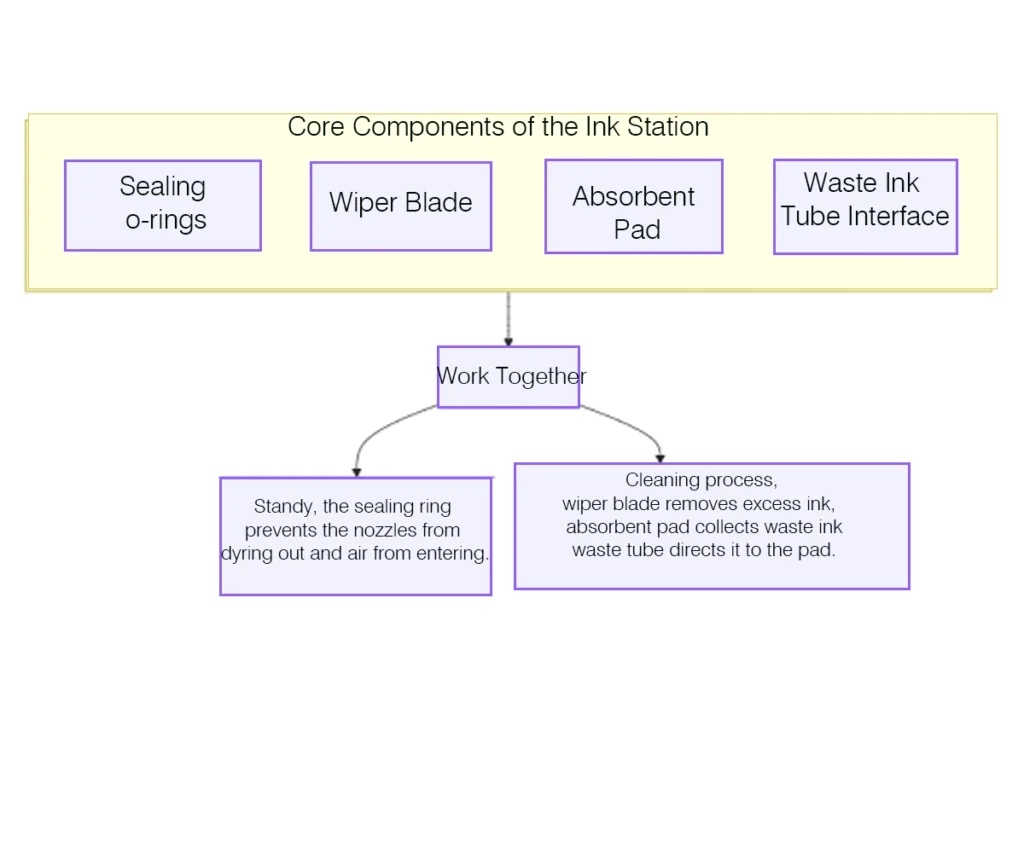

The capping station is not a single part. It includes:

| Component | Function |

|---|---|

| Seal Cap | Seals print head to prevent ink drying |

| Wiper | Cleans ink droplets from head surface |

| Ink Pad | Absorbs waste ink during cleaning |

| Waste Ink Tank | Stores collected waste ink |

Cleaning Method

- Use UV cleaning solution and lint-free wipes.

- Do not use water. Water causes crystallization and electrical risk.

- Check waste ink tank regularly. Empty before full to prevent backflow.

2) Sensor Maintenance — The “Eyes” of the Printer

The 6090 uv printer includes:

- Media height sensor

- Encoder strip sensor (grating ruler)

- Home position sensor

Cleaning Method

- Lightly wipe with lint-free cloth dipped in isopropyl alcohol.

- Do not spray liquids.

- Alcohol removes residue and evaporates quickly without leaving moisture.

4. Cooling System Maintenance: The Lifeline of The UV Lamp

The cooling liquid is essential for UV LED heat control.

Function

- Removes heat generated during curing.

- Prevents overheating and UV lamp decay.

- Offers freeze and corrosion protection for internal tubing.

Maintenance

- Check liquid level monthly (machine powered off and cooled).

- Replace coolant every 1–2 years.

- Always use manufacturer-approved UV cooling liquid.

5. Rare but Important: Core Hardware

Mainboard, motors, and belts are durable and stable components.

If they malfunction, contact professional engineers.

Do not attempt to repair these yourself.

Recommended Maintenance Schedule

| Item | Frequency | Key Action |

|---|---|---|

| Guide Rail Cleaning & Lubrication | Monthly | Apply UV solid grease to prevent ghosting |

| Sensor Cleaning | Monthly or as needed | Use alcohol, no water |

| Capping Station Cleaning | Monthly or as needed | Use UV cleaning fluid |

| Cooling Liquid Level Check | Monthly | Keep between Min–Max line |

| Cooling Liquid Replacement | Every 6–12 months | Manufacturer-specified coolant only |

| Damper / Ink Pump / Pad Replacement | Every 6–12 months | Prevent clogging and ink break issues |

Conclusion

With correct maintenance, your uv printer flatbed system will run with:

- Lower failure rate

- Higher stability

- Longer equipment lifespan

- Better return on investment

Consistent care ensures your uv flatbed printing workflow remains efficient and profitable, protecting the long-term value of your 6090 UV printer.

References

DO not use water.Epson industrial printhead guidelines emphasize using dedicated cleaning fluid instead of water to prevent crystallization and nozzle blockage .

[2] Seiko Epson Corporation. Epson Industrial Inkjet Printhead User Guide, 2020.

🤖 Ask ChatGPT about this article