Table of contents

Textile manufacturers, T-shirt customizers, and home textile producers there are always confusion about how choose their printing machine. Inkjet vs sublimation offers two strong options. Both produce high-quality prints. Each method works best with certain fabrics. Will introduce these differences helps B2B buyers save costs and improve efficiency.

What is Inkjet Printing?

Inkjet printing sprays ink directly on clothes, but sublimation printer need to transfer pattern to clothes or others. So there is big different process. Inkjet printing suitable for small custom orders. Sublimation printer suitable for big production.

Main Features for Inkjet Printing

- Widely use for cotton, polyester blends, and specialty fabrics

- Show vivid colors and sharp details

- Handles small and large production runs

- Allows easy design changes without extra equipment

Benefits of Inkjet Printing

- High precision and color accuracy

- Low setup cost

- Works well on natural fibers like cotton

- Eco-friendly water-based inks available

Maintenance Tips

- Clean nozzles regularly

- Use recommended inks only

- Calibrate colors often

- Keep the printer dust-free

What is Sublimation Printing?

Sublimation printing only use black, blue, red, yellow dye ink, no need white. The sublimation printer prints the pattern onto transfer paper first. Then a pressing machine transfers the pattern to clothing. Prints feel soft and last long. Manufacturers use sublimation for sportswear, home textiles, flags, and promotional items.

Main Features for Sublimation Printing

- Fiber material, fabric with very low cotton content

- Low cost, can print on large area

- Creates smooth gradients and continuous-tone graphics

- Uses heat press or roll-to-roll printers

Benefits of Sublimation Printing

- Vibrant colors stay after multiple washes

- Prints feel soft to touch

- Perfect for polyester products

- Fast production for bulk orders

Maintenance Tips

- Clean print heads regularly

- Calibrate heat press for accurate temperature and pressure

- Store inks properly

- Test prints often to maintain color consistency

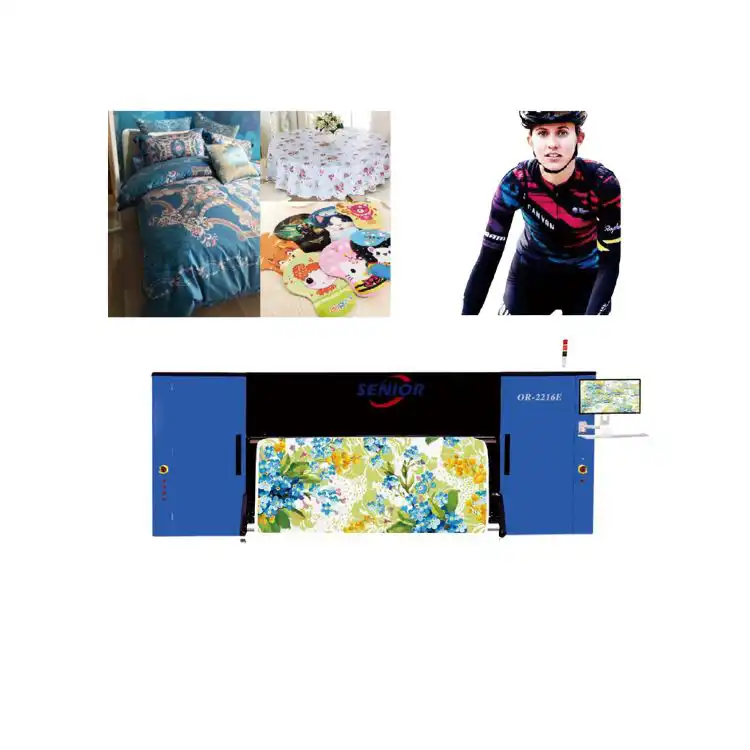

2.2-Meter Heat Sublimation Printer

Large-format sublimation printers boost production efficiency. A 2.2-meter printer works for wide fabrics and bulk orders.

| Parameter | Specification |

|---|---|

| Max Print Width | 2.2 meters |

| Print Resolution | Maximum 3600 dpi |

| Ink Type | Sublimation dye ink |

| Maximum Media Load | ≤ 10000mm |

| Printing Speed | 1 pass (360×1200 dpi): 650 sqm/h 2 pass (360×2400 dpi): 325 sqm/h |

| Color System | 4 colors (Cyan, Magenta, Yellow, Black) |

| Interface | USB / Ethernet / Wi-Fi |

| Heating System | Integrated post heater & Infrared Dryer & Fan system |

| Applications | Sportswear, home textiles, flags, banners |

This printer produces vivid colors and long-lasting use. It suits manufacturers and textile suppliers who need high output.

Inkjet vs Sublimation: Material and Thickness

| Material / Thickness | Inkjet Printing | Sublimation Printing | Typical Applications |

|---|---|---|---|

| Thin cotton (120–180 gsm) | Excellent | Not suitable | T-shirts, baby clothes |

| Medium cotton blends (180–250 gsm) | Excellent | Limited | Casual wear, promotional textiles |

| Thick cotton fabrics (250–400 gsm) | Good | Limited | Hoodies, tote bags |

| Polyester (100–300 gsm) | Good | Excellent | Sportswear, flags, home textiles |

| Polymer-coated surfaces | Limited | Excellent | Mugs, phone cases, metal panels |

Inkjet works best on cotton and natural fibers. Sublimation excels on polyester and coated materials.

Factors B2B Buyers Should Consider

- Fabric type. Cotton favors inkjet. Polyester favors sublimation.

- Order volume. Inkjet works for small batches. Sublimation works for bulk orders.

- Design complexity. Fine details show better on inkjet. Bold, vibrant designs shine with sublimation.

- Cost efficiency. Compare ink, fabric, and energy costs.

- Durability. Sublimation prints last longer on polyester fabrics.

Choosing the Right Printing Technology

Use Inkjet Printing for:

- Cotton fabrics

- Small, high-resolution batches

- Flexible design changes

Use Sublimation Printing for:

- Polyester and coated surfaces

- Large orders requiring vibrant, durable prints

- Feel soft, fade-resistant

2.2-meter roll-to-roll sublimation printer allows fast production. It is suitable for manufacturers and textile suppliers.

Conclusion

Inkjet and sublimation printing both provide advantages. According to your material and order size, you can choose the right machine. Inkjet vs sublimation helps B2B buyers know which method they need. It improves efficiency, reduces costs, and delivers high-quality products to customers.