A New Way to Design Apparel

The apparel world is changing fast.

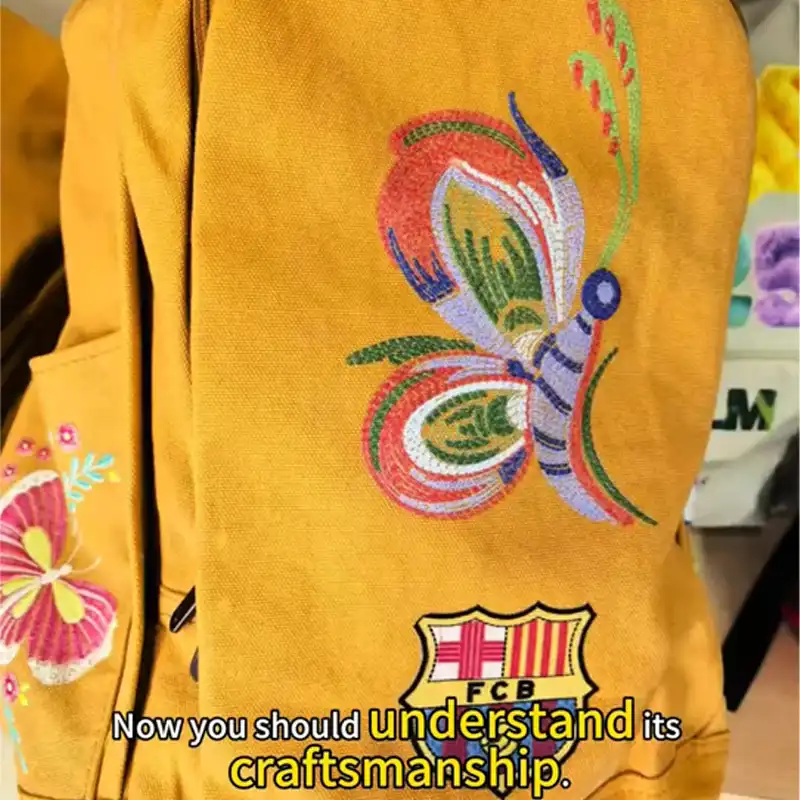

More T-shirt makers, shirt factories, and luxury brands now use digital embroidery machines instead of traditional stitching.

Why? Because they want faster production, cleaner results, and modern textures that stand out.

A digital embroidery machine lets you print embroidery-like textures directly onto fabric.

It keeps the 3D raised look but removes the need for needles, threads, or hours of setup.

You upload a file. The printer does the rest.

Read more about our Digital Embroidery Machine.

What Exactly Is a Digital Embroidery Machine?

It’s a printer that mimics embroidery.

It prints layers of ink to form texture, height, and depth just like real thread.

The result looks stitched, feels raised, and stays flexible.

You can use it on cotton, polyester, leather, canvas, or denim.

No more thread breaks. No tension issues. No messy rework.

It’s pure digital control.

Why More Brands Are Switching

B2B buyers want consistent results, lower costs, and faster production.

Digital embroidery machines deliver all three.

Key Advantages

- Fast output. A logo prints in minutes, not hours.

- Low cost. No need to create embroidery files or setups.

- Same look every time. Perfect for mass production.

- Multi-surface use. Works on almost any textile or synthetic.

- Premium finish. The 3D texture feels real and luxurious.

- Eco-friendly. Less waste, less power, less material use.

How It’s Used in Fashion

| Application | Fabric Type | Typical Thickness | Recommended Height |

|---|---|---|---|

| T-shirt logos | Cotton / Poly blend | 0.5–1 mm | 1.2 mm |

| Polo badges | Piqué | 1.5 mm | 1.8 mm |

| Dress shirt labels | Poplin / Fine cotton | 0.3–0.6 mm | 0.8 mm |

| Leather tags | PU / Genuine leather | 1–2 mm | 2.0 mm |

| Jacket patches | Canvas / Denim | 2–3 mm | 2.5 mm |

This flexibility makes digital embroidery ideal for custom apparel lines, small luxury runs, and brand logos on mixed materials.

Simple Daily Maintenance

Digital embroidery machines are easy to maintain.

Maintenance Checklist

- Wipe print-head before.

- Shake ink gently each day.

- Check UV lamps weekly.

- Keep the printing table clean.

- Run a quick nozzle test every morning.

These five habits keep prints sharp and consistent.

Digital vs Traditional Embroidery

| Feature | Digital Embroidery | Traditional Embroidery |

|---|---|---|

| Setup Time | 1–2 min | 20–30 min |

| Small Batch Cost | Low | High |

| Material Range | Wide | Limited |

| Editing Design | Instant | Requires rework |

| Maintenance | Easy | Complex |

| Speed | Fast | Slow |

Digital embroidery wins in flexibility and speed.

It’s built for modern production lines, not manual labor.

How to Choose the Right Machine

When buying a digital embroidery machine, focus on:

- Print area and height. Match your product types.

- Printhead model. Epson i3200 or similar gives sharp results.

- Software control. Easy layer adjustment saves time.

- After-sales support. Choose a supplier that offers parts and training.

- Optional tools. Laminators or heat presses enhance finish quality.

You need a balance of speed, accuracy, and durability.

Why It Matters for Apparel Brands

Digital embroidery shortens production time and expands design freedom.

Factories can print a new logo sample within minutes.

Luxury brands can offer small-batch customization without high setup costs.

T-shirt and shirt producers can maintain consistent branding on every material.

It helps you say “yes” to custom orders and still meet deadlines.

The Future Is Digital

Digital embroidery machines are not just printers.

They are a smarter way to create texture, identity, and value.

They bring speed to sampling, accuracy to branding, and quality to every piece you produce.

If you make T-shirts, shirts, or luxury apparel, this is your next big upgrade.

Fast. Clean. Profitable.