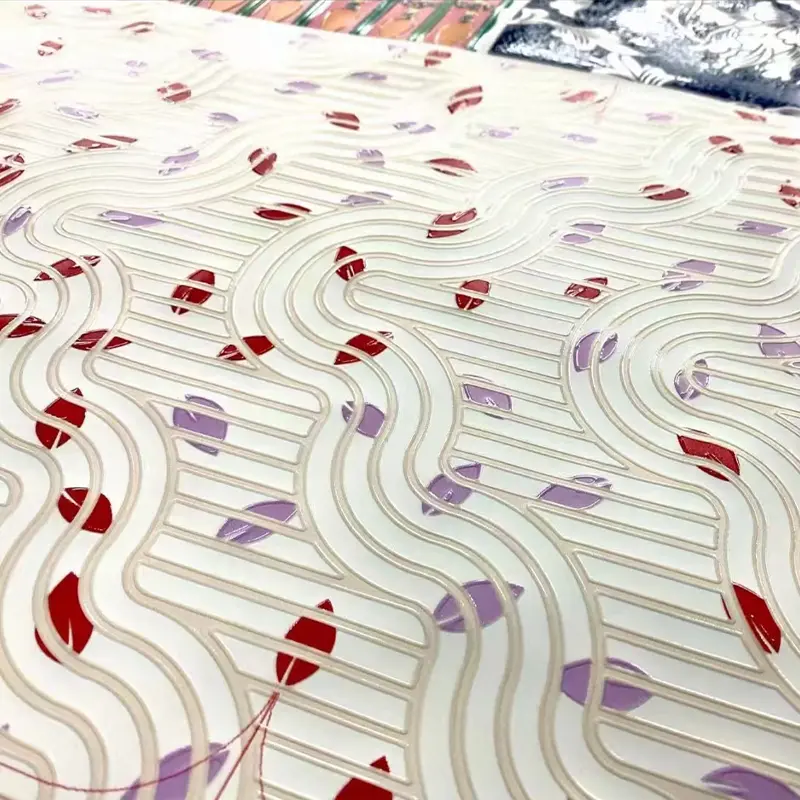

Embroidery printing uses a UV Printer or a UV flatbed printer to create raised, textured layers that mimic stitched embroidery. The 3D effect is achieved by stacking layers of white ink, which cures and solidifies as it prints. Unlike traditional embroidery, there are no needles or threads involved, so the process does not damage the material and works with delicate textiles.

UV embroidery printing can be done with different types of machines:

- UV Roll-to-Roll (DTF) Printers – suitable for continuous, flexible materials like fabric rolls.

- UV 6090 Flatbed Printers – ideal for small-batch customizations on flat surfaces such as bags, leather patches, or apparel.

The workflow typically includes designing the pattern digitally, printing it with the UV printer, and applying a transfer film. For fabric applications, the printed design is placed on a heated panel at around 120°C, allowing the heat-activated adhesive to bond the pattern to the material. A final pressing step with a protective film increases durability, resulting in a finished embroidered look.

Compared to traditional embroidery, UV embroidery printing offers:

- Precise replication of stitch textures

- Complex color gradients and vibrant designs

- Faster production and lower cost

- Compatibility with a wider range of materials, including leather, synthetics, and hard surfaces like wood and acrylic

Applications include fabric labels, clothing patches, shoes, caps, bags, custom merchandise, and even hard surfaces, making UV embroidery printing a versatile alternative to traditional methods.

Embroidery-like printing on fabric

What Is Embroidery Printing with UV Printer?

Embroidery printing uses a UV DTF printer or UV flatbed printer to create raised textured layers. The ink cures and becomes solid as it prints. The final result has a 3D embossed surface that feels like stitched embroidery thread. The printed effect can follow curves, outlines, and color gradients more easily than real thread embroidery.

You can apply the printed design to:

- Fabric labels

- Clothing patches

- Shoes and caps

- Bags, luggage and custom merchandise

- Leather and synthetic leather

- Hard surfaces like wood and acrylic

There are no needles and no thread, so the process does not damage the material and works with fragile textiles.

Why Manufacturers Are Switching to UV Embroidery Printing

Traditional embroidery delivers a premium, textured finish, but it comes with several limitations. Stitching a standard logo on a single cap can take 8–12 minutes, meaning hundreds of pieces require many hours of machine operation. It also demands skilled operators, and reproducing complex designs or gradients is difficult and time-consuming.

UV embroidery printing addresses all these challenges. The printing process is fast, cost-effective, and flexible, producing raised, 3D embroidery-like effects in seconds rather than minutes. It works equally well for small or large batch orders, making it ideal for on-demand customization.

Other advantages include:

- Lower production costs, especially for small quantities

- Vibrant colors and smooth gradients, overcoming the limitations of thread colors

- Precise replication of intricate designs, regardless of pattern complexity

- Consistent quality from the first piece to the last

- Easy reprints, with no need to digitize stitches or adjust machine settings

By eliminating the restrictions of needle-and-thread embroidery, UV embroidery printing allows manufacturers to deliver high-quality, visually striking designs faster, cheaper, and with far greater creative flexibility.

Material Thickness and Application Comparison

The feel of the embroidery effect depends on the printed ink thickness. Different industries prefer different thickness levels.

| Thickness (mm) | Look & Texture | Best Use Cases | Notes |

|---|---|---|---|

| 0.3 – 0.6 mm | Light raised effect | Fabric labels, children’s clothing, shirts | Very soft, flexible, comfortable to touch |

| 0.6 – 1.0 mm | Standard “thread-like” embroidery look | Hat logos, cloth patches, brand badges | Good balance between raised feel and durability |

| 1.0 – 2.0 mm | Strong 3D embossed effect | Shoes, bags, leather goods, keychains | Feels more like molded stitching; premium appearance |

| 2.0 – 3.0 mm | Heavy embossed decorative style | Hard goods, luxury packaging, high-end display items | Less flexible; more suitable for rigid surfaces |

Choosing thickness depends on comfort, material flexibility, and desired visual weight.

Embroidery printing on leather

Common Industry Applications

1. Apparel Decoration (Caps, Jackets, Uniforms)

Brands use UV embroidery printing to show detailed logos. Color borders stay sharp. Production time is short. It is great for seasonal product runs.

2. Shoe and Bag Branding

Embossed, thick textures enhance a luxury feel. UV printing handles leather, PU, and coated fabrics well.

3. Custom Patches and Badges

Factories print patch sheets and then heat-press or sew them onto garments. This method reduces stitching costs drastically.

4. Brand Labels and Tags

Printed 3D crystal labels can replace woven labels on products like backpacks, sportswear, and outdoor equipment.

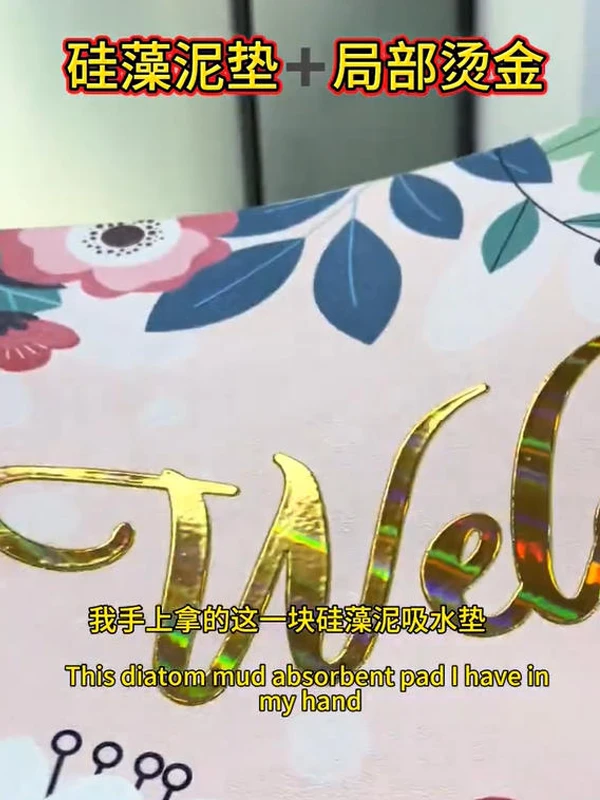

UV Printed Embroidery Transfer Technology for Socks

Socks + UV embroidery-like transfer effect is truly stunning. Using UV printing technology, three-dimensional embroidery textures are printed directly onto the fabric. After printing, a specialized transfer B film is applied using a laminator, ready for transfer. The highly realistic embroidery-like pattern is cut out and precisely positioned on the sock surface. Transfer is performed using a bottom-heated heat press set to approximately 120°C. During transfer, a cloth or towel is placed over the pattern to ensure even pressure and heat distribution. After the initial transfer, a secondary pressing step enhances adhesion and durability. The final result features three-dimensional, crisp embroidery with distinct layers. This technique achieves stable, durable UV-printed embroidery effects even on elastic sock materials.

UV Printing Embroidery Like for socks

Advantages of Embroidery Printing with UV Printer

- Fast turnaround for bulk production

- Works on many materials including leather and stretch fabric

- Consistent quality, no broken threads or stitch errors

- Fine details and small text remain clear

- Less operator skill required than traditional embroidery

- Easy customization for small batch or personalized products

Daily Maintenance Tips for UV Embroidery Printing Machines

Good workflow keeps productivity high. Here are practical maintenance habits for workshop operators:

- Keep print head and wiper clean every day

- Use original ink or validated ink to prevent clogging

- Maintain stable humidity (45%–65%) to avoid drying issues

- Shake white ink bottles daily to prevent pigment settling

- Store film and materials in a dust-free environment

- Do a nozzle check at start and finish of each shift

These steps prevent downtime and maintain color consistency.

Is It a Replacement for Traditional Embroidery?

Not in all cases. Real embroidery still has a unique sewn texture on high-end tailored clothing. But for branding, quantity production, small logos, and flexible material use, UV embroidery printing offers faster delivery, higher detail, and lower cost.

Most successful manufacturers now use both. Embroidery machines handle classic items. UV printers handle complex and fast-turnover jobs.

Final Thoughts

Embroidery printing with a UV printer gives apparel and label manufacturers a strong production advantage. It delivers a high-value look with lower labor, faster output, and wider material compatibility. For factories where customer order patterns change rapidly, this is a scalable and profitable production method.

If you are planning to upgrade your workshop, add UV embroidery printing as a complementary process. It increases product range and opens new market opportunities.