What Is 3D Silicone Heat Transfer Technology?

3D silicone heat transfer is an innovative process that combines UV high-precision color printing with heat press application. This technology creates raised silicone labels and logos without any silicone molds, making production faster, more flexible, and more cost-effective. It offers a 3D embossed effect similar to real silicone patches.

Wide Range of Material Options for Silicone Heat Transfer Labels

UV-printed 3D silicone heat transfer labels support various special-effect materials, including:

- gold and silver metallic finishes

- iridescent / rainbow effects

- lenticular 3D floating effects

- glossy, matte, and glow-in-the-dark materials

These raised silicone labels are ideal for streetwear, outdoor apparel, sportswear, and brands that need eye-catching 3D visual effects.

Features of UV 3D Printing Silicone Heat Transfer Labels

Real Physical 3D Texture

Unlike flat printing methods, UV 3D printing builds real raised layers through digital ink stacking. The result is a true embossed texture you can feel with your fingers. This makes the silicone heat transfer label stand out with a physical 3D structure rather than a visual illusion.

It delivers multi-level 3D height options—from slight elevation to thicker embossed layers. UV 3D printing captures fine details with excellent precision, making it suitable for complex logos and labels.

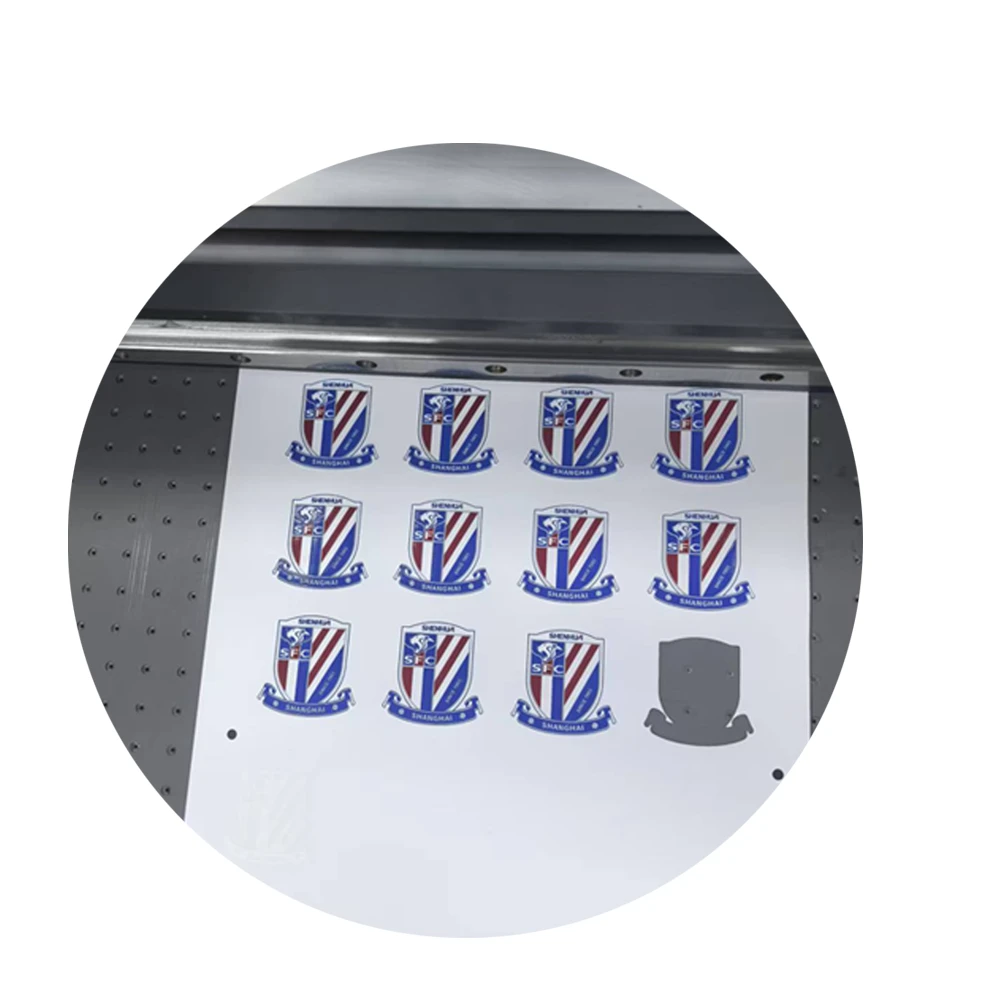

High Efficiency and Fully Digital Production

UV 3D printing requires no plates or screens. No film, no mesh, no mold. Designs can be printed instantly from the computer, making it ideal for fast sampling, small batches, and personalized production.

Design changes cost nothing—just update the file. No mold waste, no plate replacement. Every silicone heat transfer label stays consistent, even when each design is unique.

Material Advantages

UV color printing provides sharp, high-resolution graphics.

The label resists deformation and rubbing.

Soft touch and skin-friendly, offering comfortable wear.

Compared with woven heat transfer labels or PU heat transfer labels, UV 3D silicone labels provide a softer texture and a more premium raised effect.

Customizable 3D Thickness Options

0.3mm / 0.5mm / 0.8mm / 1.0mm

Multiple thickness options are available: 0.3mm, 0.5mm, 0.8mm, 1.0mm.

UV 3D printing delivers uniform height, strong raised layers, and clearly defined textures.

Perfect for brand logos, premium apparel, outdoor gear, and sportswear applications.

Fully Customizable Shapes

Any shape can be created based on your artwork.

Flat, round, square, curved, irregular, hollow-out shapes, and micro-text are all supported.

UV 3D printing captures fine edge detail accurately, ideal for complex patterns.

Multiple Surface Finishes

Matte, glossy, gold, silver, iridescent, gradient colors, embossed textures, micro-textures, and excellent wash durability are available.

These surface options make UV 3D printing silicone labels more visually attractive than traditional woven heat transfer labels or PU heat transfer labels.

How to Apply 3D Digital Silicone-Like Heat Transfer Labels

Positioning

Place the printed 3D silicone-like transfer logo onto the garment, shoe upper, bag, or hat.

Ensure the surface is clean, smooth, and wrinkle-free.

This ensures the flock heat transfer label or raised logo adheres evenly.

Recommended Heat Press Settings

For the best adhesion results:

Heat press temperature: 160°C

Pressure: 4 kg

Time: 20 seconds

Increase 1–2 seconds for thicker 3D raised effects.

llow the label to cool naturally before peeling or moving the fabric.

Important Notes

Ensure the fabric is dry and free of dust or oil.

For waterproof or stretch fabrics, test a small area first.

Use a professional heat press for best results.

Customization Options for Silicone-Like 3D Heat Transfers

Custom Logo / Artwork

Supports brand logos, sports symbols, letters, and graphics.

Handles complex shapes, fine text, and full-color UV printing.

Ideal for custom heat transfer labels for clothing that require precision.

Color Customization

Solid, gradient, or multi-color options.

Special finishes: metallic gold/silver, glossy, matte, embossed textures.

Creates premium 3D visual effects similar to raised silicone transfers.

Surface Effect Options

Metallic finish

Iridescent

Lenticular 3D

Glow-in-the-dark

These effects enhance the visual impact of flock heat transfer labels or silicone-style transfers.

Minimum Order Quantity

UV printing allows extremely flexible production.

Even complex designs can be produced with no minimum order.

Perfect for sampling, small-batch brands, and custom apparel projects.

Why Choose Silicone-Like Heat Transfer Labels?

Silicone-like heat transfer labels are eco-friendly, durable, customizable, and cost-efficient.

They are widely used for clothing, footwear, bags, and outdoor gear.

Compared with PVC patches, embroidery, or woven labels, they offer:

Strong 3D depth that upgrades brand presentation.

Excellent wash durability and skin-friendly comfort.

Eco-friendly materials.

Supports a wide range of creative finishes.

Compatible with many materials, including cotton, polyester, nylon, leather, and stretch fabrics.

Summary of 3D Digital Silicone-Like Heat Transfer Labels

3D digital silicone-like labels use high-precision UV color printing combined with heat transfer application.

This process requires no silicone molds and creates raised badges and logos that look and feel like real silicone.

It is flexible, eco-friendly, low-cost, and ideal for fast production.

As a result, 3D silicone heat transfer labels have become a premium branding solution for clothing, footwear, bags, and outdoor gear.

They are also suitable for brands needing custom heat transfer labels with strong texture and high-end visual appeal.

Frequently Asked Questions

Q: What is a 3D Digital Silicone Heat Transfer Label?

A 3D digital silicone label combines UV 3D printing with heat press application to create raised, silicone-like badges, logos, and designs.

No silicone molds are needed.

Perfect for clothing, footwear, bags, and outdoor gear.

This is an excellent reference for how to make heat transfer labels with realistic 3D textures.

Q: What’s the difference between 3D silicone labels and traditional silicone labels?

3D silicone labels: Built with UV 3D printing, no mold needed. Short lead time, low cost, even single-piece production is possible.

Traditional silicone labels: Require molds, long production time, and high cost. Best suited for mass production.

Q: How thick can 3D digital silicone labels be?

Supports multiple thickness options: 0.3mm, 0.5mm, 0.8mm, 1.0mm.

Thickness can be customized based on brand style and application.

Ideal for how to make heat transfer labels with precise raised effects.

Q: What shapes can be customized?

Fully customizable: flat, round, square, curved, irregular, hollow, micro-text.

UV 3D printing ensures precise edges, perfect for complex designs.

Q: What surface effects are available?

Available finishes: matte, glossy, gold, silver, gradient, embossed, textured, lenticular 3D, glow-in-the-dark.

Achieve trendy and premium visual effects.

Q: Are 3D digital silicone labels washable?

Yes, they are washable.

Perfect for clothing, bags, and gear that require durability.

UV 3D printing ensures the raised design remains intact even after washing.