In metal signage, awards, and premium customization, traditional etching processes are often complex and costly.

With the development of UV printing on Metal, a plate-free digital etching solution is replacing conventional methods, making metal processing faster and more efficient.

What Is UV Printing on Metal Etching

UV etching with UV printing refers to printing a protective etching ink directly onto metal surfaces using a flatbed UV printer.

The printed areas resist chemical etching, while exposed areas are etched to create relief textures.

No plates, no screen printing, and no film exposure are required.

Areas to be preserved are protected by printed etching ink.

Unprotected areas are exposed to chemical etching, creating precise recessed metal patterns.

UV Printing on Metal as a Masking Solution

In UV printing on metal, the printed ink acts as an etching mask.

The UV ink protects selected areas from acid or alkaline solutions, while uncovered metal is etched.

After etching, the ink can be easily removed to reveal clean and precise metal textures.

UV Print on Metal – Two Common Etching Methods

There are two main ways to apply UV print on metal for etching purposes.

One method involves direct decorative printing on metal surfaces.

The second and more common method uses UV printing as a masking layer for chemical etching, producing deeper and more dimensional results.

Key Properties of UV Etching Ink for Metal

UV etching ink must resist strong acids during the etching process.

It also requires high adhesion, fast UV curing, and sharp edge reproduction.

After etching, the ink should be removable without damaging the metal surface.

Importance of Metal Surface Pretreatment

Metal surfaces are usually smooth and require proper pretreatment before UV printing.

Cleaning, degreasing, and coating help improve ink adhesion and ensure stable etching results.

Good pretreatment directly affects final quality and durability.

Visual Positioning in UV Metal Etching

Visual positioning systems enable UV printers to scan metal sheet positions automatically.

Designs are aligned precisely with real products, reducing setup time and positioning errors.

This is especially useful for small and complex metal parts.

Advantages of UV Printing on Metal

UV printing on metal offers plate-free production and simplified workflows.

It delivers sharp edges, strong depth, and high efficiency.

This makes it ideal for customized and small-batch metal manufacturing.

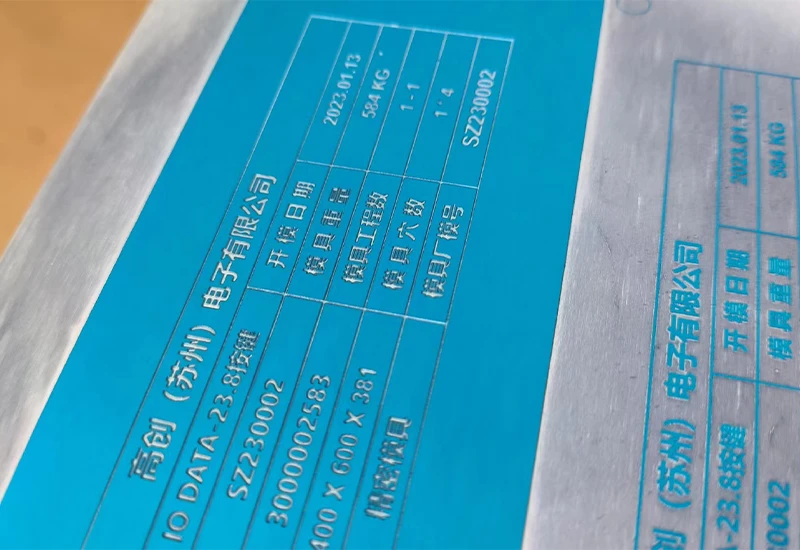

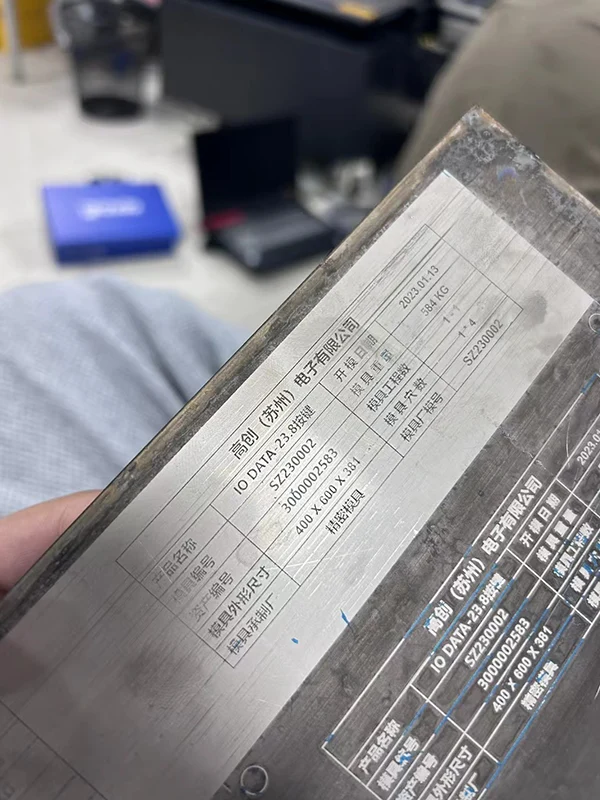

Applications for Metal Signs and Awards

UV metal etching is widely used for metal signs, awards, and premium decorative products.

Applications include etched nameplates, trophies, medals, and crystal labels.

One UV flatbed printer can support multiple high-value metal processes.

Conclusion

UV etching combines traditional metal processing with digital UV printing technology.

It offers efficiency, flexibility, and precision for modern metal signage and customization industries.

Looking for a UV printer for metal etching?