Hot foil stamping and silver foiling are popular surface finishing techniques widely used in gift packaging, helmet customization, phone cases, creative merchandise, stainless steel products, IP derivatives, furniture decoration, logo labels, and luxury packaging.

Traditional hot foiling usually requires plate making, which increases cost and limits flexibility. By contrast, a flatbed UV printer combined with varnish printing and foil lamination technology enables plate-free foiling and dual-color effects, allowing gold and silver finishes to be applied on the same product with high precision.

Why Can’t a Flatbed UV Printer Print True Gold or Silver Directly?

Many customers ask the same question:

If a flatbed UV printer can print full color, why can’t it print gold or silver directly?

The reason is simple.

True gold and silver colors rely on metallic particles, and these particles cannot be jetted through a UV printhead.

The metallic shine of gold and silver comes from metal powder. However, UV printheads use extremely fine nozzles.

Each nozzle is about 10 microns in size, thinner than a human hair.

A single printhead contains more than 1,600 nozzles.

Metal particles are too large to pass through these micro nozzles. If used, they would clog the printhead. For this reason, a flatbed UV printer cannot directly print real gold or silver ink.

The Solution: hot foil stamping (Gold & Silver)

The solution is hot foil stamping through lamination.

First, the design is printed with special UV varnish.

Then gold or silver foil is transferred onto the varnish layer using heat and pressure.

This process creates a bright, metallic gold or silver effect without damaging the flatbed UV printer, while maintaining high precision and durability.

How Does a uv flatbed printing Achieve Dual-Color Foil Effects

The principle of UV foiling is simple and efficient.

A uv flatbed printing is first used to print a dedicated varnish layer for foiling.

Then, a heat press transfers gold or silver foil onto the varnish surface.

To achieve dual-color effects such as gold and silver, the process is repeated in two separate steps.

Complete hot stamping foil Process

Step 1: Print the Silver Foil Area → Apply Silver Foil

Set the areas that require silver hot stamping foil in the RIP software.

The flatbed uv printer the first varnish layer for silver foiling.

Place the silver foil film over the printed design.

Use a heat press to laminate the foil.

Recommended temperature: 65–70°C.

Peel off the foil film after pressing.

At this stage, the silver foil area is completed.

Step 2: Register and Print the Gold Foil Area → Apply Gold Foil

This is the most critical step.

Place the finished silver-foiled product back onto the alignment guides of the UV6090 flatbed UV printer.

Print the varnish layer for gold foiling with precise registration.

Apply the gold foil film over the printed area.

Use a heat press for foil transfer.

Recommended temperature: 65–70°C.

Peel off the foil film after pressing.

Once completed, the final product features a dual-color foil effect with both gold and silver.

The above describes one method for achieving dual-color foiling.

An alternative solution is introduced in the next section.

First Foiling Step (Using Gold Foil as an Example):

- Print the Gold Foil Area with Adhesive:

· Load your prepared design file into the uv flatbed printing.

· Select only the gold foil layer for printing. The printer precisely applies a layer of clear or white UV adhesive onto the areas that require gold foiling.

· White adhesive is recommended for better coverage and to make the gold color appear more vibrant on dark substrates.

2.Apply the Gold Foil Film:

· Immediately after printing the adhesive, manually or with an auxiliary device, lay the gold foil film over the entire printed area. Ensure the foil side faces up and the release liner contacts the adhesive. Make sure it is smooth and free of air bubbles.

3.UV Curing and Foil Removal:

· Activate the UV lamps on the printer to cure the adhesive. The UV adhesive instantly hardens under ultraviolet light, firmly bonding the gold foil to the areas with adhesive.

· After curing, carefully and evenly peel off the gold foil film. The foil remains only where the adhesive was applied, while areas without adhesive reveal the substrate or previously printed design. The first gold foiling step is now complete.

Second Foiling Step (Silver Foil):

- Precise Registration:

· This is the most critical step, testing both technical skill and equipment stability.

· Do not move the substrate: Ideally, the substrate should remain on the flatbed UV printer platform after the first foiling.

· Software alignment: Load the previously prepared silver foil layer in the RIP software. Use the registration marks from the first print and the printer’s camera-based alignment system (if equipped), or make fine adjustments in the software to ensure the silver layer aligns perfectly with the gold layer—no gaps, no overlap. - Print the Silver Foil Adhesive:

· Once alignment is confirmed, print the adhesive for the silver foil layer. The printhead precisely applies UV adhesive only to the designated silver areas.

3.Apply Silver Foil and UV Curing:

· Immediately cover the printed silver adhesive with the silver foil film.

· Perform a second UV curing cycle.

· After curing, peel off the silver foil film. At this stage, both gold and silver foils appear precisely on the same design, achieving a perfect dual-color foiling effect.

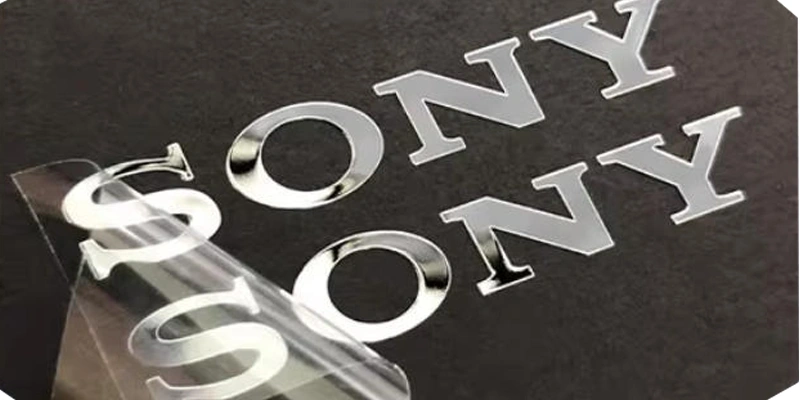

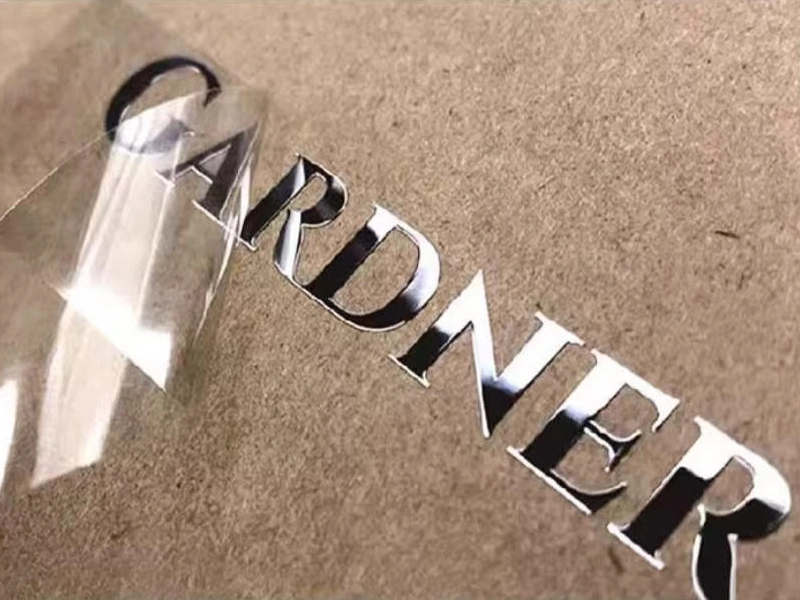

Final Effect Highlights (Eye-Catching Results)

The dual-color foiling effect offers:

- Extremely high metallic shine

- Strong 3D depth and fullness

- Simultaneous display of gold and silver

- No plate making required

- Suitable for small-batch production

- Scratch-resistant and durable surface

The finished product can be easily applied to almost any material, including acrylic, glass, metal, TPU, PP, PET, helmets, wood, leather, stainless steel, and more.

UV Crystal Labels: Full-Color Printing with Gold & Silver Foiling

Our team has surpassed the limitations of traditional uv dtf printer cheap (crystal labels), which could only print in full color.

We now fully support:

- Gold foiling

- Silver foiling

- Dual-color foiling (gold + silver)

A wide range of metallic colors is also available, including:

- Green gold

- Royal blue gold

- Red gold

- Rose gold

- And many other metallic finishes

For unique colors or custom metallic effects, our engineers can provide specialized development services.

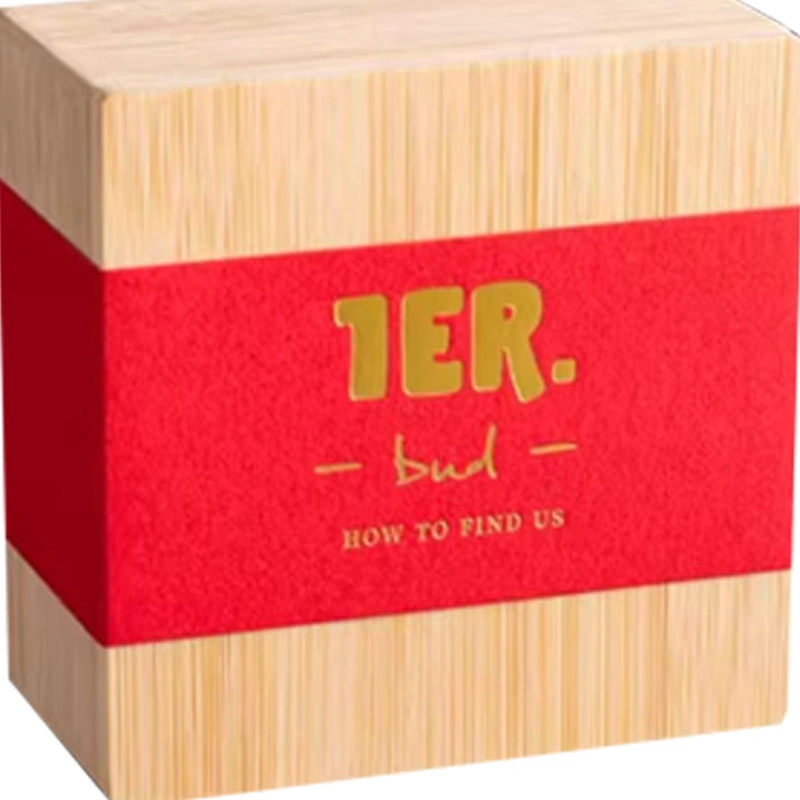

Application Examples

Dual-color hot stamping foil is ideal for:

- Helmet designs & logos

- Phone cases & AirPods cases

- Acrylic standees

- Gift box packaging

- Cosmetic packaging

- Creative merchandise & IP products

- Premium labels

- Furniture decorative panels

- Customized sneakers

A single uv dtf printer for sale can complete full-color printing along with gold and silver hot stamping foil. The process is flexible, and the visual effect is highly striking.