In printer uv flatbed applications, the choice of fixtures plays a critical role in determining printing accuracy, stability, and final product quality.

Especially for spherical objects, small-sized irregular products, and partial logo customization, achieving high-quality results is nearly impossible without proper fixture support.

Many customers often ask:

How does a flatbed uv printer 6090 print logos on spherical objects such as balls?

The answer is simple:

Professional printing fixtures are essential for precise positioning and stable fixation.

In practical applications, a cylinder uv printer relies on dedicated fixtures to securely hold spherical products in place, ensuring consistent print height, accurate logo alignment, and repeatable results during production.

Why Fixtures Are Essential for Spherical Printing with a Flatbed UV Printer 6090

Spherical products such as table tennis balls and golf balls have the following characteristics:

- Curved surface

- Lightweight and easy to roll

- Small printing area (partial logos)

- High precision requirements

If you place the ball directly on the printing platform without a fixture, it is nearly impossible to control its position. Print head height, logo alignment, and repeatability can all be affected.

Therefore, when using a flatbed UV printer 6090 to print on spherical objects, fixtures are an indispensable tool to ensure stable positioning and high-quality output.

- The 6090 Flatbed UV Bottle Printer: This is the recommended basic printer for spherical object printing.

- Dedicated Table Tennis Ball Fixture (Jig): This is the key to success. The fixture should have:

- High Precision: It can securely hold the table tennis ball, ensuring concentric rotation and preventing misalignment during printing.

- Adaptability: Ideally, it can hold multiple balls at once (e.g., 4 or 6) to improve production efficiency.

- Rotational Mechanism: It can be manually indexed for rotation or connected to the printer’s control system via a motorized rotary axis. The latter allows automated multiple-pass printing to cover the entire ball surface or specific areas.

- Specialized UV Ink: Must be selected for ABS plastic with good elastic adhesion. Standard rigid inks are prone to cracking or peeling when the ball is impacted.

Table Tennis Ball for the Digital UV 6090 Flatbed Printer

Using table tennis balls as an example, we typically employ dedicated table tennis printing fixtures:

- Custom grooves designed according to the ball diameter

- Ensure the balls are stable and do not roll

- Guarantee consistent logo placement on each ball

Simply place the table tennis balls into the fixture one by one, and they can be directly printed using the digital UV 6090 flatbed printer.

Printing Advantages:

- Supports simultaneous printing of white ink, color ink, and varnish

- Bright colors with clear layering

- Fine and precise logos with strong adhesion

- Simple operation and easy to use

In uv printer cylinder for table tennis ball logos, the efficiency and flexibility far exceed traditional printing methods, making it ideal for customization and small-batch production.

Why Traditional Printing Struggles with Small-Batch Ball Customization

In practice, it is common to encounter requests such as:

- Customers ordering only 3–5 boxes of golf balls

- Multi-color logos

- Frequently changing designs

For traditional printing methods, such as screen printing or pad printing, these requests are particularly challenging:

- Plate making is required

- High production costs

- Small quantities are not cost-effective

- Multi-color registration is difficult

Many traditional factories directly refuse such orders.

The advantages of the digital UV 6090 flatbed printer are exactly reflected here:

- No plate making required

- Supports small-batch or even single-piece customization

- Designs can be changed freely

- Especially suitable for personalized and customized requests

This highlights the significance of having a compact 6090 uv bottle printer for small-sized production.

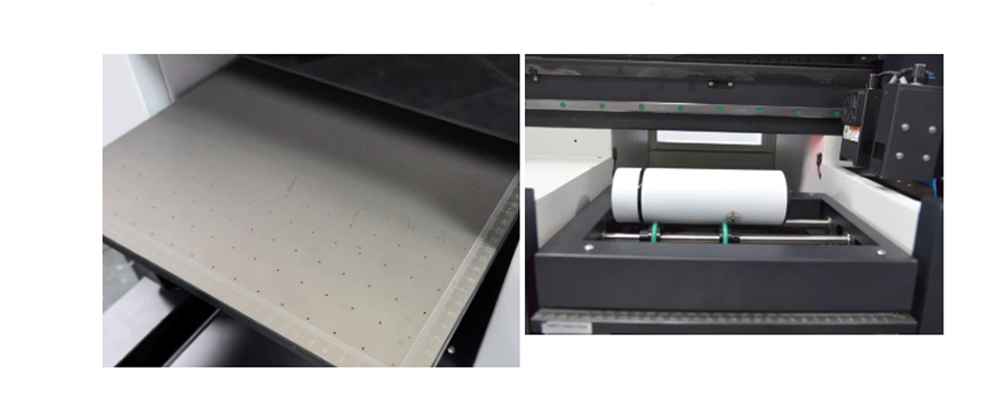

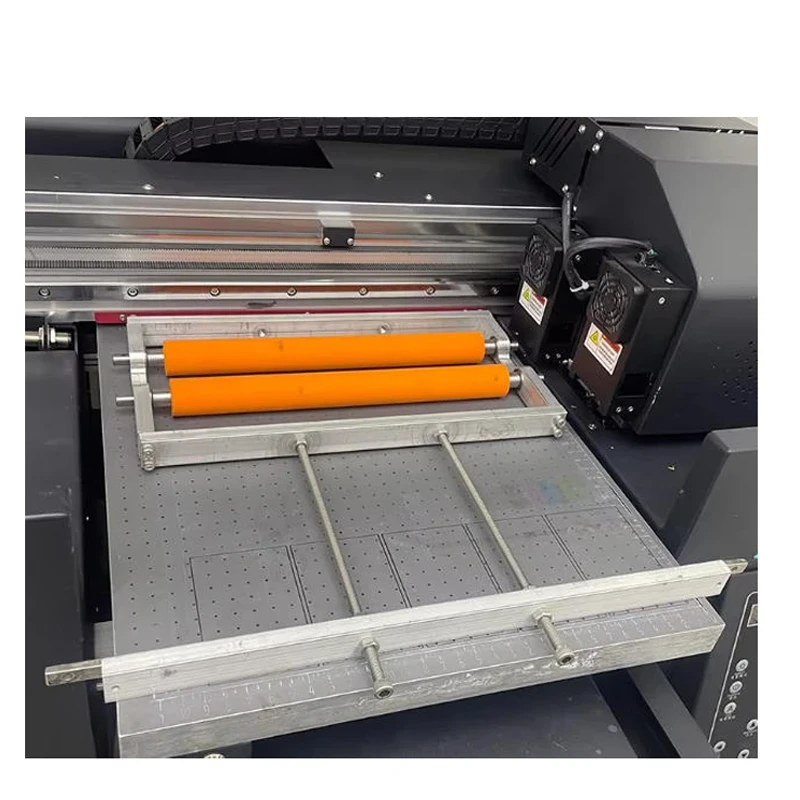

different cylinder printer fixtures show

Common Types of uv cylinder printer Fixtures

Depending on the product shape, uv cylinder printer fixtures can be mainly divided into the following categories:

Spherical Printing Fixtures

- Applicable to: Table tennis balls, golf balls, etc.

- Features: Specialized groove positioning, high stability

- Application: Ball logos and small design customization

Cylindrical Printing Fixtures

- Applicable to: Cylindrical pens, tubular products, small bottles

- Features: Secures the cylinder in place, prevents rolling

- Application: Logo customization for cylindrical products using a china cylinder uv printer

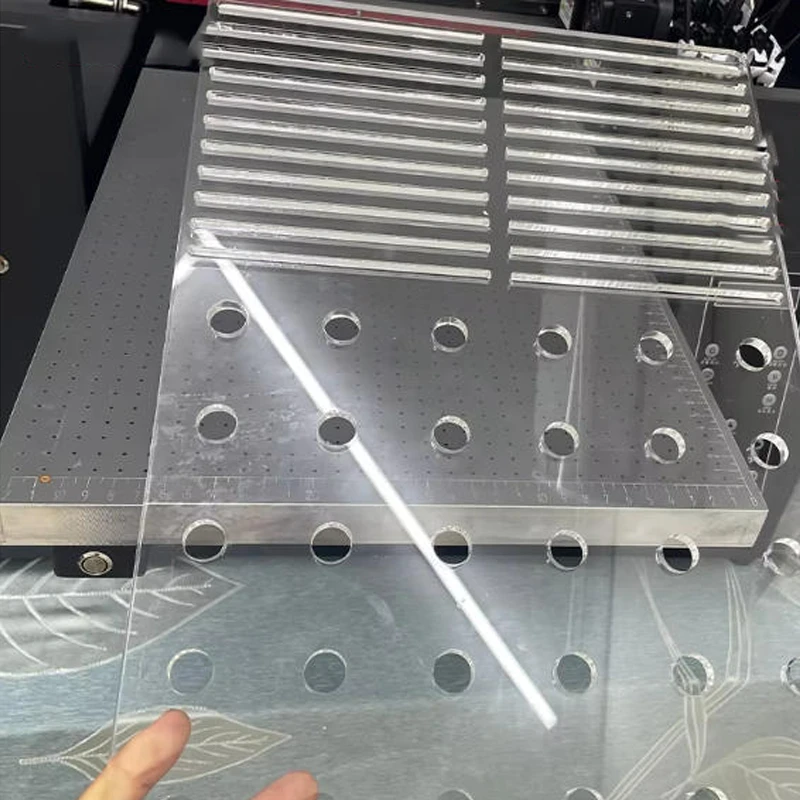

Hemisphere + Half-Cylinder Composite Fixtures

A very practical combination fixture design:

- Half for spherical objects (e.g., table tennis balls)

- Half for cylindrical objects (e.g., pens)

With the same fixture, different products can be printed simultaneously. For example:

- Print table tennis ball logos at the same time

- Print pen logos at the same time

This greatly improves equipment utilization and production flexibility when using a cylinder uv printer.

Common Material Choices for uv printing news Fixtures

In uv printing news applications, the choice of fixture materials is equally critical. Currently, commonly used fixtures are mainly divided into metal fixtures and acrylic fixtures, each with its own advantages in terms of cost-effectiveness and production efficiency.

Metal Fixtures

- Advantages: High strength, durable, suitable for long-term, large-scale production

- Applicable Scenarios: Factory-level, stable mass production

Acrylic Fixtures

- Advantages: Lower cost, flexible manufacturing, suitable for diverse customization

- Applicable Scenarios: Small batches, prototyping, customized orders

Overall, orders requiring high repeatability and stability are better suited for metal fixtures, while small-batch, multi-specification, frequently changing customized orders are better served by acrylic fixtures. Choosing the right fixture material according to actual production needs ensures high printing precision while achieving greater production efficiency and cost-effectiveness, especially when using a uv dtf prints.