When selecting and operating a UV printer machine, the configuration and quality of its core components directly determine printing precision, stability, production efficiency, and the overall lifespan of the machine. Many users focus solely on price or print quality when purchasing equipment, overlooking the critical internal structures that truly play a decisive role.

This article provides a professional, systematic analysis of the core components of a 3D UV printing machine and their functions, helping you more accurately assess the true performance of a UV print machine.

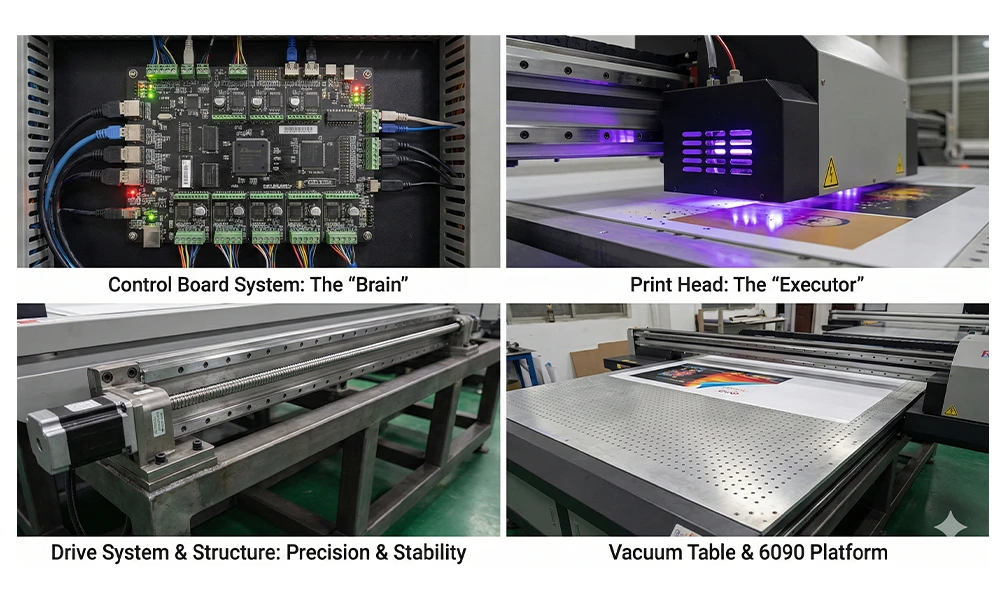

Print Head of UV Print Machine

The Core Component of UV print machine

The print head is the absolute core of the entire best UV printing machine. All images, text, and colors are ultimately achieved through the precise ejection of ink droplets by the print head.

How Printheads Work

After image processing via RIP software, the control system outputs preset parameters to the printhead for precise UV LED printing machine on material surfaces.

Core Performance Metrics for Printheads

Accuracy: Directly determines image detail.

Speed: Impacts output per unit time.

Stability: Determines continuous production capability and maintenance costs.

The quality of printheads directly influences UV Machine for printing results, production efficiency, and long-term operational stability. They represent the most critical component requiring focused attention in UV printing machine price configurations.

Control Board System of uv printing machines

The “Brain” of UV Printing Machines.

If the printhead is the “executor,” then the control board serves as the central nervous system of the UV digital flatbed printing.

Functions of the Control Board

Controls inkjet nozzle logic

Coordinates movement across all axes

Processes RIP data and transmits commands

Determines color accuracy and operational stability

The performance of the control board directly impacts:

Color consistency across printed images

Long-term operational stability

Frequency of errors or data interruptions

A mature, stable control board system is an indispensable core component for industrial-grade UV printing machines.

Vacuum Table for uv dtf printing machine

Ensures material stability and prevents nozzle scraping incidents

The vacuum table functions by firmly securing materials to the UV DTF printing machine platform via negative pressure, preventing material bulging or curling during printing.

The Critical Role of Adhesion Platforms in flatbed uv led printer Stability and Safety

Prevent material movement causing ghosting.

Avoid material warping that scrapes the printhead.

Enhance consistency and safety in flatbed UV LED printers.

High-quality adhesion platforms typically feature:

Strong tensile strength.

Resistance to deformation.

Long-term stability.

Platform material and machining precision directly impact service life and actual printing safety.

Ball Screw Drive System for uv led flatbed printer (Grinding Ball Screw)

A Critical Component Determining Ink Placement Precision.

The grinding ball screw primarily handles precision transmission for the X/Y axes, offering the following advantages:

High-precision alignment.

Stability maintained during high-speed movement.

Effective reduction of ink placement errors.

Compared to conventional transmission structures, the grinding ball screw:

Offers superior wear resistance.

Maintains higher precision retention.

Significantly enhances UV ink placement accuracy.

This is an indispensable key component in a high-precision UV LED flatbed printer.

Flatbed uv printing machine Beam Guide Rail System (Linear Guide Rail)

Ensures stable carriage operation without vibration

The primary function of the beam guide rail is to guarantee that the flatbed UV printing machine carriage operates with:

Smooth travel.

No shaking.

No deviation.

A stable guide rail system can:

Improve overall printing accuracy.

Prevent streaks or ghosting caused by vibration.

Extend the lifespan of printheads and mechanical components.

Higher-quality guide rails enable smoother carriage movement and more consistent digital UV flatbed printer results.

Servo Motor for uv led flatbed printing machine

Precise Control of X/Y-Axis Movement

The servo motor controls the movement of the X and Y axes in UV LED flatbed printing machine, offering the following advantages:

Precise positioning

Rapid response speed

High repeatability accuracy

Compared to standard stepper systems, servo systems provide:

More stable motion control

Reduced operational errors

Enhanced overall production efficiency

This is particularly crucial for high-precision, high-speed A4 UV digital flatbed printers.

Core Control Principle of digital uv flatbed printing machine (Closed-Loop Control)

- Command Issuance: The digital UV flatbed printing machine control system (mainboard/RIP software) sends X/Y-axis movement distance, speed, and acceleration commands to the servo driver based on pattern data.

- Motor Execution: The driver converts commands into electrical signals, driving the servo motor to move the lead screw/belt, achieving linear motion of the X-axis (printhead carriage) and Y-axis (media platform).

- Real-Time Feedback: The motor’s built-in incremental/absolute encoder continuously collects rotational speed and position data, transmitting it back to the driver.

- Deviation Correction: The driver compares the “target position” with the “actual position,” instantly adjusting output current to correct motor movement errors, ensuring precise positioning for every movement.

Key Parameters for X/Y-Axis Control in digital flatbed led uv printer price

- Positioning Accuracy: Must be controlled within ±0.01 to ±0.05mm to prevent pattern misalignment and ghosting during multi-pass printing; absolute encoders offer superior precision compared to incremental encoders.

- Speed Stability: Optimized acceleration/deceleration curves prevent impact jitter during printhead starts/stops, reducing banding and ink dot misalignment—especially critical for 6-pass/8-pass high-precision modes.

- Rigidity Matching: The X-axis (printhead) requires high rigidity to prevent wobbling during high-speed movement; the Y-axis (media) requires flexible adaptation to prevent stretching and deformation of the substrate.

Case: 6090 uv printer Parameter Analysis

To gain a more intuitive understanding of the actual performance of the core components mentioned above, we will use the 6090 UV printer as an example to examine the configuration and dimensions of these components in actual uv printer 6090 on the market.

Parameters for 6090 uv flatbed printer

The Senior 6090 UV flatbed printer supports 1–4 printhead configurations (compatible with models like Epson TX800, i1600, or i3200), accommodating varying production efficiency and precision requirements. Higher printhead counts and models deliver superior print speed and resolution performance. This model features a China UV 6090 printer size of 60×90 cm and an adjustable print height range from 3 mm to 240 mm, accommodating everything from thin flat materials to thicker three-dimensional objects. The UV flatbed printer 6090 platform, also measuring 60×90 cm, securely holds materials to prevent shifting or curling during printing, effectively protecting the printhead and ensuring the best 6090 UV printer quality. It supports multiple ink color combinations and RIP software control systems, further enhancing color reproduction capabilities and print result stability.

digital uv 6090 flatbed printer Base Frame Structure / All-Steel Frame Structure

The Foundation of the Entire digital UV 6090 flatbed printer.

The all-steel frame or base grid structure serves as the foundational load-bearing platform for UV printer 6090.

Its stability and manufacturing quality directly impact:

Consistency in printing accuracy

Resistance to deformation during prolonged operation

Overall service life of the machine

A high-rigidity, low-vibration all-steel structure maintains equipment precision without degradation over extended use, representing a key characteristic of the industrial-grade China UV 6090 printer.

6090 uv printer Power & Circuit System

The Foundation for Stable Operation of the Entire Machine

The power supply system is responsible for providing stable electrical output to the entire 6090 UV printer. Its quality directly impacts:

Whether the printhead operates stably

Whether circuit boards are susceptible to interference

Whether errors or abnormal shutdowns occur frequently

If the power supply system and wiring design are inadequate, the following issues may easily arise during production:

Print interruptions

Data errors

Equipment malfunction alerts

A stable, interference-resistant power supply system is crucial for ensuring the reliable operation of the entire machine.

Core Requirements for Power Supply Systems

Voltage Stabilization and Filtering

Equipment must feature high-precision switching power supplies or UPS uninterruptible power supplies to deliver stable output of rated voltages required for printheads, mainboards, and motors (e.g., 24V DC, 380V/220V AC). These systems must filter out grid noise and voltage spikes. Particularly for UV digital flatbed printing and high-pass mode devices, voltage fluctuations exceeding ±5% may cause printhead ink interruptions, banding, or ghosting.

Power Matching

The power supply’s rated power must exceed the combined power consumption of all digital UV flatbed printer components (including peak power for printhead ignition, UV lamp curing, and servo motor operation) to prevent frequent device reboots and printing stuttering due to insufficient power.

Grounding Protection

Independent grounding must be implemented (grounding resistance < 4Ω) to prevent static electricity buildup from damaging printheads or motherboards, while also safeguarding operators and equipment from electrical leakage. Grounding is particularly critical in static-sensitive applications such as textile digital UV flatbed printing machines and crystal label UV print machine.

Conclusion

Understanding Core Components is Key to Selecting the Right uv machine for printing.

A truly stable, efficient, and durable uv printer machine is not determined by any single component alone. Rather, it results from the coordinated operation of multiple core components, including the printhead, control board, drive system, platform structure, and power supply system.

When selecting or evaluating uv printing machines, prioritize the following:

Printhead configuration and stability

Control system and circuit board maturity

Mechanical structure precision and rigidity

Power supply and overall material quality

Only by truly understanding these core components can you select a flatbed uv led printer solution that meets your production needs and delivers long-term stable operation.