As demand for customization continues to grow in packaging, apparel accessories, gifts, and branding, ribbon print machine technology is also evolving.

Beyond traditional screen-printed webbing processes, ribbon print machine are emerging as a more flexible, efficient, and precise modern printing solution.

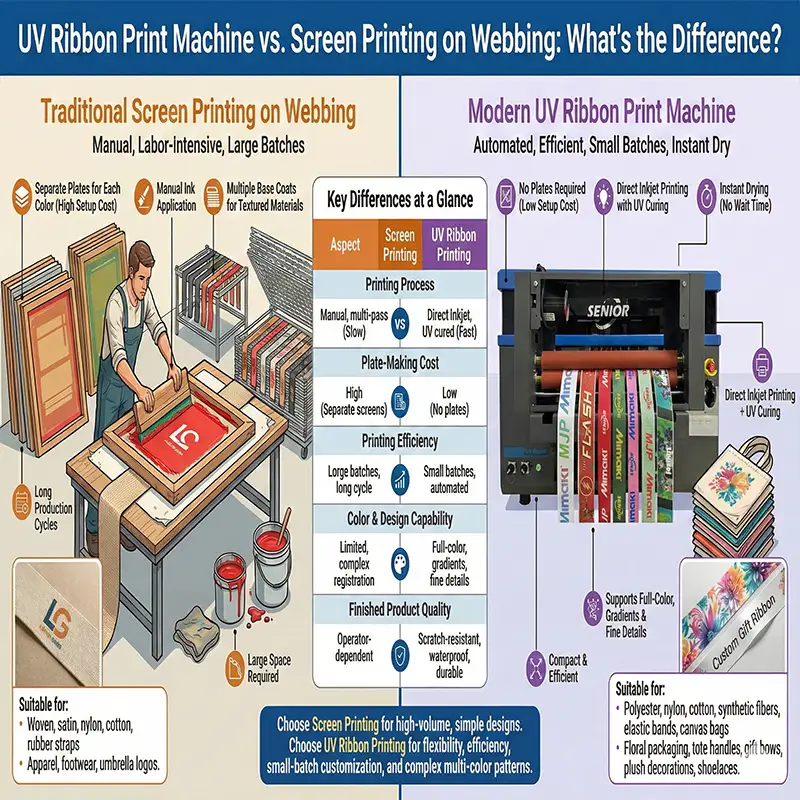

This article compares ribbon print machines with screen-printed ribbons across process principles, print quality, production efficiency, and application scenarios to help you make a clearer choice for your business needs.

What is Screen Printing on Webbing

Traditional screen printing on webbing relies heavily on manual labor, requiring large spaces and being a labor-intensive printing method.

Characteristics of Screen Printing Process

- Uses screen templates, requiring separate plates for each color

- Manual ink application using squeegees during printing

- Thicker or textured webbing materials may require multiple base coats (typically 3-4 layers) before pattern colors

- Number of color passes determined by final appearance; may require one, two, or multiple passes

- Process relies heavily on experience and operator skill, resulting in relatively low efficiency

Suitable Materials and Applications

Suitable for printing on woven straps, satin ribbons, nylon straps, rubber straps, and cotton straps

Commonly used for printing trademarks or logos on apparel, footwear, umbrellas, bags, etc.

Strong capability for printing patterns on flexible strap materials, but involves complex operations and lengthy production cycles

Limitations

Requires large production space and incurs high labor costs

Difficult to achieve color registration, making multi-color or gradient patterns challenging

Low efficiency for small-batch, multi-style orders

Ribbon print machine for Printing on Webbing

The printer ribbon machine utilizes UV-curable ink, which instantly solidifies under ultraviolet light to directly print patterns onto the webbing surface. No plates are required, and no drying time is needed—prints are dry immediately. This process meets modern businesses’ demands for speed and flexibility.

Advantages of UV custom ribbon printing machine

No plates required; simple operation

Supports multi-color, gradient, fine line, and small font printing

Fast printing speed, ideal for small-batch, multi-style production

Low material requirements: compatible with polyester, nylon, cotton, synthetic fibers, and elastic bands

Scratch-resistant, abrasion-resistant, and waterproof prints

Applications for ribbon label printer machine

The print on ribbon machine not only prints on various types of webbing but also directly prints on canvas bags. Common applications include:

Ribbons for floral packaging

Handle straps for tote bags

Bow decorations for gift boxes

Decorations for plush toys

Shoelaces, lanyards, ID badges, backpack straps, etc.

When ribbon label printing machine on canvas bags, simply secure the bag with clamps and print the design directly. No subsequent drying or processing is required—it’s fast, convenient, and ready to use immediately.

Ribbon print machine vs Screen Printing on Webbing: A Comparison

| Comparison Aspect | Screen Printing on Ribbons | UV Ribbon Printing |

|---|---|---|

| Printing Process | Uses screen stencils and manual ink scraping; requires multiple passes for base coating and color printing | Direct inkjet printing with UV lamp curing; instant drying |

| Plate-Making Cost | Each color requires a separate screen, resulting in high setup costs | No plate-making required; flexible and efficient |

| Printing Efficiency | Manual operation; suitable for large batches with long production cycles | Automated printing; efficient even for small-batch production |

| Color & Design Capability | Multi-color and gradient designs are difficult; color registration is complex | Supports full-color printing, gradients, and fine details |

| Material Compatibility | Suitable for webbing, satin, nylon, cotton, and rubber straps | Compatible with almost all ribbon materials and canvas bags |

| Finished Product Quality | Highly dependent on operator skill; limited abrasion resistance | Scratch-resistant, wear-resistant, waterproof; stable and durable prints |

| Application Scenarios | Apparel, footwear, umbrellas, bags, and brand labels | Ribbons, canvas bags, gift packaging, tote bags, plush toys, and more |

Which printing machine for ribbon Method Is Best for Your Business?

Small batches, multiple styles, fast delivery

Fabric ribbon printer machine are the preferred choice

Flexible design modifications without plate making

Production starts from a single piece

Quick printing of full-color and gradient patterns

Ideal for gift customization, brand promotion, and special occasion needs

High-volume, repetitive production

Screen-printed ribbons still hold advantages

Suitable for large quantities, simple designs, and single-color printing

Remains viable for cost-sensitive businesses

Summary

Ribbon print machine and traditional screen printing processes each have their respective applications.

Printer ribbon machine offers advantages such as flexibility, efficiency, instant drying, compatibility with multiple materials, and the ability to print multi-color, diverse patterns. It is particularly well-suited for modern businesses’ small-batch customization needs and varied application scenarios.

Screen-printed webbing suits high-volume, repetitive production but relies heavily on labor, space, and operational expertise, making multi-color or gradient designs challenging.

By understanding the differences between these two processes, you can select the most suitable printing method for your business needs, achieving efficient, stable, and high-quality production results.