Growth Trends in the Customized Wood Products Market

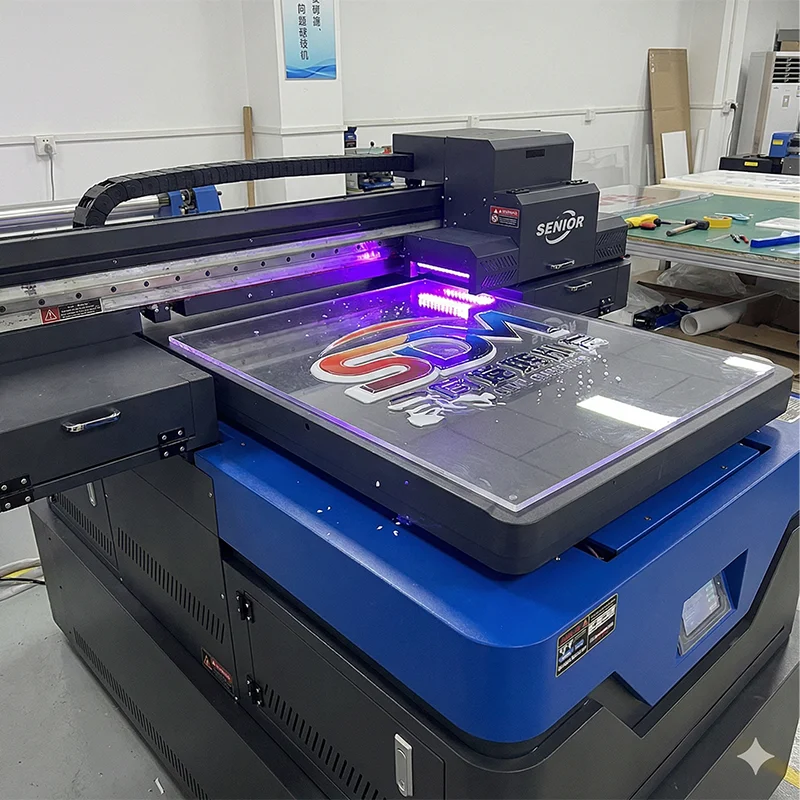

The customized wood products market grows quickly. Customers want products that stand out. They look for high quality and personalization. Creative designs grow in demand. Technology moves forward, and eco-friendly materials gain popularity. Businesses rely on small UV printers to produce wood products quickly and meet customer expectations.

What is UV printing?

UV print on wood is a digital printing method that uses UV-cured inks to print directly onto wooden surfaces.

Unlike traditional printing or engraving, UV printing delivers vivid colors, strong adhesion, and fast curing on both natural and engineered wood.

UV printing is a digital printing method that uses ultraviolet light to cure UV ink instantly. This UV printer can print on glass, metal, wood, acrylic, leather, and plastic, delivering bright colors and a long-lasting finish. It requires no plates and produces no extra waste, making it ideal for custom gifts, signs, packaging, and décor. Both small runs and large projects can be handled efficiently, turning ideas into finished products with stable quality and high flexibility.

Case

UV 6090 flatbed printer UV Printing jewelry box

Introduction to UV Printing Technology

UV printing cures ink instantly with ultraviolet light. It prints sharp and precise patterns on almost any surface. A piezoelectric printhead sprays tiny UV ink droplets accurately. UV-LED light (365-405nm) cures the ink in fast. A uv inkjet printer produces bright colors and intricate designs fast.

UV Print on Wood—Pros & Cons

| Aspect | UV Print on Wood |

|---|---|

| Color Vibrancy | High |

| Adhesion | Strong |

| Drying Time | Instant |

| Suitable Wood Types | MDF, plywood, solid wood |

| Limitations | Not ideal for deep textures |

Why UV Printing Works Perfectly on Wood Surfaces

Wood is porous. Traditional inks soak in and blur lines. UV ink cures instantly. It stays on the surface. Lines stay crisp. Colors stay vibrant. Details remain sharp. Fine text and complex patterns print perfectly. Both uv 3d printers and small UV printers handle wood surfaces with precision and consistency.

Advantages of UV Printing for Custom Wood Products

UV printing creates prints that stick firmly. The cured layer resists has scratches, wear, water, and UV light. It works well for furniture, signage, decorative items, and other durable wood products. Businesses achieve high-quality results every time.

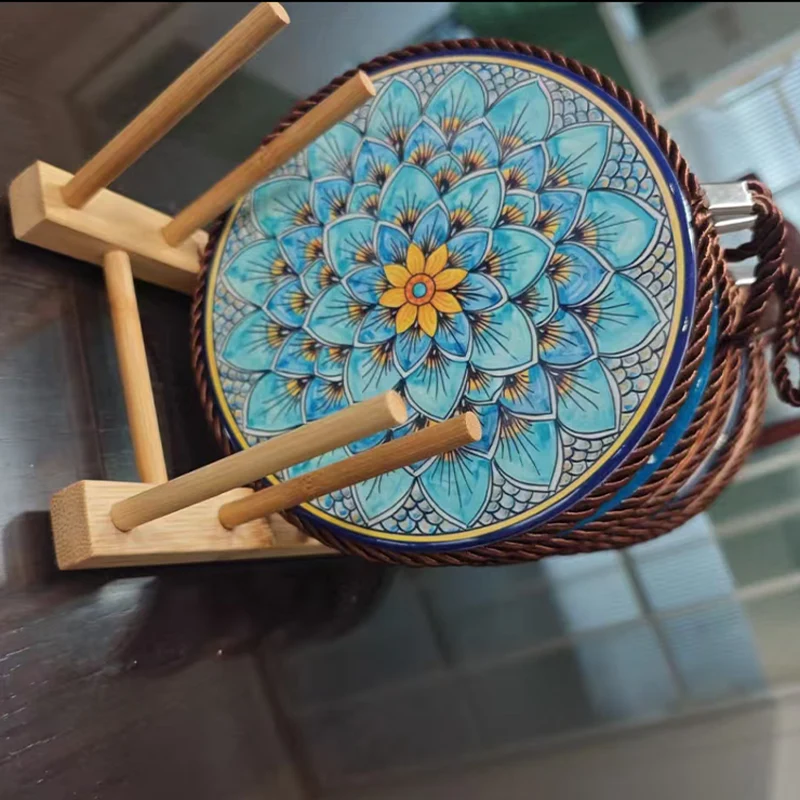

Popular Wood Products Printed with UV printing

UV printing works best for small batches and complex patterns. It offers high precision, instant drying, strong adhesion, and 3D effects. Popular products include:

- Wooden boxes and jewelry boxes

- Wooden puzzles

- Wooden musical instruments

- Custom furniture panels

- Wooden building materials

A small UV printer can handle all these products efficiently and produce consistent results.

- Tips for UV Printing Wood Products

Follow these tips to boost both quality and efficiency:

Maintain wood moisture at 8–12%.

Three steps: coarse (120 grit), medium (240 grit), and fine (400 grit). Always sand along the grain. For curves, wrap sandpaper around a sponge for smoother results.

Apply primer at 0.08–0.15 mm on porous wood. Keep layers thin to avoid cracking.

For light-colored wood, use a single coat of white ink. For dark wood, apply two or more coats for accurate colors.

A uv inkjet printer ensures precise layering and vibrant results every time.

Future Trends in UV Printing for Customized Wood Products

UV printing will turn wood products into creative and interactive pieces. Trends focus on smart technology, eco-friendly materials, stronger visual effects, and new applications. Businesses using uv 3d printers or small UV printers will lead the personalized wood product market.

Conclusion

UV printing cures ink instantly. It prevents smearing and penetration issues. Prints stay sharp, colorful, and detailed. UV inks stick well, resist wear, and adapt to custom shapes. They offer multiple effects and fast production. UV printing widely use for on furniture, crafts, signage, musical instruments, building materials, and custom wood products. Businesses can use a UV inkjet or UV 3D printer to showcase designs directly, efficiently, and with a professional finish.

FAQ

Q1: Can UV printing be done directly on wood?

Yes. UV printing can print directly on wood surfaces without lamination or transfer film, as long as the surface is flat and properly prepared.

Q2: Is UV print on wood durable?

UV-cured inks bond well to wood and offer good resistance to scratching and fading, especially for indoor and semi-outdoor applications.

Q3: What types of wood are best for UV printing?

MDF, plywood, bamboo, and coated wood panels provide the most consistent results for UV printing.

Q4: What is the most critical factor for UV print on wood?

The most critical factor for UV print on wood is proper surface preparation.

Untreated natural wood is highly absorbent. If UV ink is printed directly onto raw wood, the ink can penetrate into the fibers before it is fully cured by the UV lamp, resulting in blurred colors, ink spreading, and poor image quality.

To achieve stable and high-quality results, the wood surface must be pre-treated—such as sealing, priming, or applying a clear coating—to prevent ink absorption. A properly prepared surface allows the UV ink to remain on the surface and cure instantly, ensuring sharp details, vivid colors, and strong adhesion.