Acrylic is one of the most popular materials for custom décor, signage, gifts, displays, and creative merchandise. When producing acrylic products, the two main methods are:

UV DTF Sticker → Apply a printed sticker onto acrylic

UV Direct Printing → Print directly onto the acrylic sheet

Both deliver clear graphics, but they differ in appearance, texture, durability, speed, and applications.

This guide provides a full comparison of uv dtf printing, especially for brands using a uv printer acrylic, uv printer for acrylic, or an acrylic business uv dtf printer.

Acrylic UV DTF Printing

Process: The design is printed on a PET release film using UV inks.

A layer of hot-melt powder is applied and cured with heat.

This forms a transfer layer.

The film is pressed onto the acrylic surface using a heat press.

After cooling, the PET film is removed, and the design is fully transferred.

Key Feature: “Print first, transfer later.”

The printed layer and adhesive film exist as a separate transfer sheet.

Acrylic UV Direct Printing

Process: The design is printed directly on the treated acrylic surface using a UV flatbed printer.

UV light cures the ink instantly.

The ink bonds tightly to the material.

Key Feature: “Direct printing.”

Ink and acrylic form a single fused layer.

Visual Finish|Acrylic Result with UV Direct Printing vs uv dtf printing

UV Direct Printing

The ink cures directly on the acrylic surface.

The design becomes part of the acrylic.

No film edges.

Rich colors and sharp details.

Supports white ink, multilayer printing, gloss/matte finishes.

Enables texture and 3D embossing effects.

Ideal for premium acrylic merchandise and displays.

UV DTF Sticker on Acrylic

The design is printed on a film, then applied to acrylic.

Visible film edges may reflect light.

A slight sticker thickness can be felt.

Clear result, but less seamless than direct UV printing.

Summary

UV Direct Printing = Seamless, premium finish

UV DTF = Good quality, slight sticker appearance

DTF on acrylic vs. Direct UV Printing

| Printing Method | surface | cost | surface | Durability | Color Accuracy |

| DTF on acrylic | logo, small pattern | $$ | Acrylic | Medium | Good |

| Direct UV Printing | color+white+color+UV stamping | $$$ | Acrylic | High | Excellent |

Durability|UV Direct vs UV DTF

UV Direct Printing: Strongest adhesion, scratch-resistant.

UV DTF: Good but still a film.

Edges may lift; large areas may trap bubbles.

Texture & Special Effects

UV Direct Printing offers embossing, texture, and varnish effects.

UV DTF cannot achieve these 3D or gloss-selective layers.

Production Speed|Efficiency Comparison

UV Direct Printing: Best quality, slower for mass production.

UV DTF: Batch printing and fast transfer allow high-volume production.

Application Stability

UV Direct Printing provides stable results.

UV DTF depends on manual application, which may introduce errors.

Best Use Cases for UV DTF and UV Direct Printing

Golden Use Cases for UV DTF Printing

- Supports Curved Surfaces and 3D Edge Wrapping

This scenario focuses on objects with curves, edges, and 3D shapes. UV DTF printing is ideal when the product is not a flat acrylic sheet, but a cylinder, rounded corner plate, or small accessory.

Typical items include acrylic nameplates with wrapped edges, acrylic cups, pen holders, cosmetic containers, USB cases, and phone stands.

Because UV DTF uses a flexible adhesive film, it wraps edges smoothly like skin, without cracking or leaving white gaps—an effect that UV direct printing on acrylic cannot achieve.

For small creative businesses, this method works perfectly with an acrylic business UV DTF printer, especially when handling mixed 3D surfaces.

- Material Versatility and Cross-Industry Applications

This use case is perfect for businesses handling multiple materials beyond acrylic. With UV DTF printing, the same artwork can be transferred onto acrylic, metal, wood, glass, helmets, laptops, and more.

This flexibility makes UV DTF ideal for small custom studios and DIY shops. With one UV DTF printer and a heat press, you can support dozens of substrates without switching equipment.

If your studio frequently handles acrylic products, UV DTF film works great alongside a uv printer for acrylic or uv printer acrylic setup, allowing you to cover both flat and irregular surfaces efficiently.

- Pursuing Specific Textures and Visual Effects

Some projects require a specific tactile finish or glossy surface. UV DTF printing delivers a wide range of texture options—from matte to high-gloss—because the adhesive layer itself adds thickness.

This makes UV DTF ideal for high-end toy models, tactile signage, branded logos, and decorative appliance panels.

When your acrylic products require a premium look without investing in advanced UV texture printing, UV DTF becomes a practical choice, especially for acrylic business UV DTF printer users.

- Flexibility in Orders and Fast Turnaround

UV DTF printing is ideal for businesses handling small, mixed, or urgent orders. You can pre-print UV DTF transfer films in bulk and keep them in stock.

When an order arrives, simply heat-press the film onto acrylic and ship within minutes.

This workflow is extremely efficient and avoids powering up a large uv printer acrylic flatbed machine for every small batch.

For studios preparing for holiday peaks, UV DTF provides unmatched speed and flexibility.

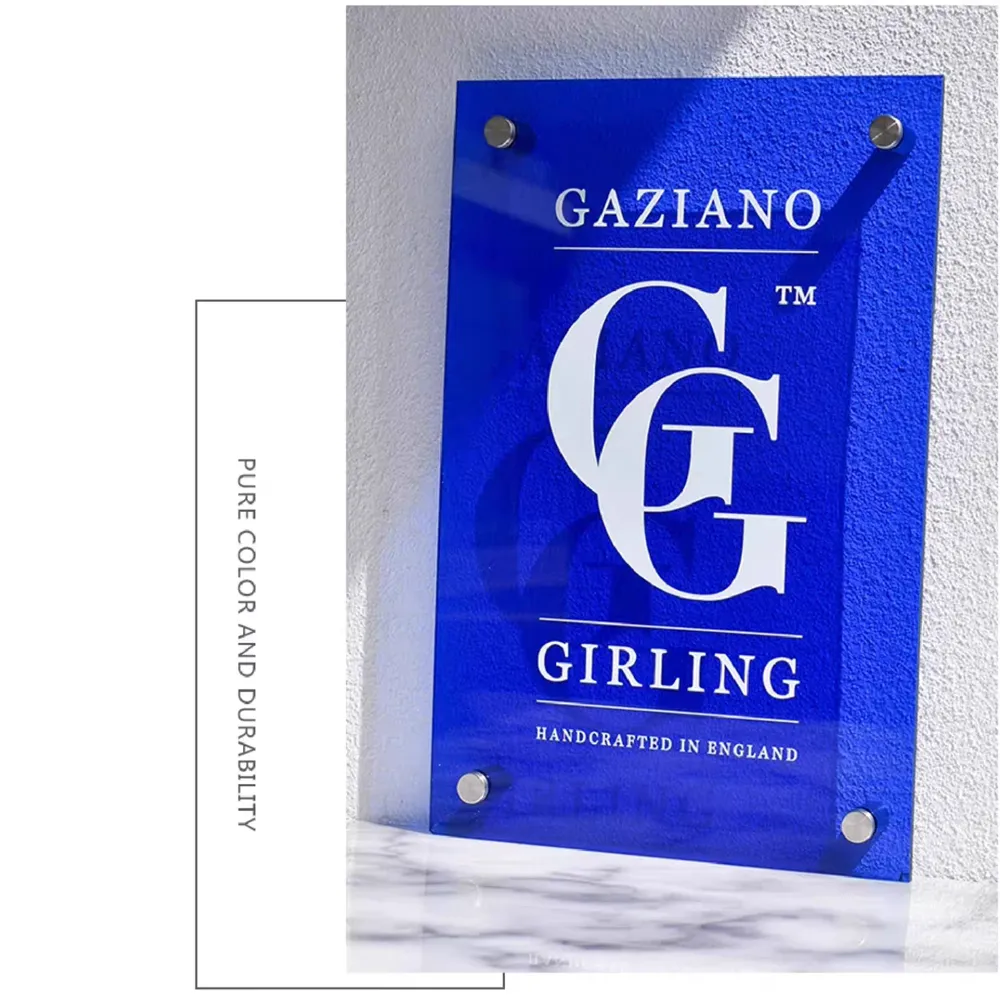

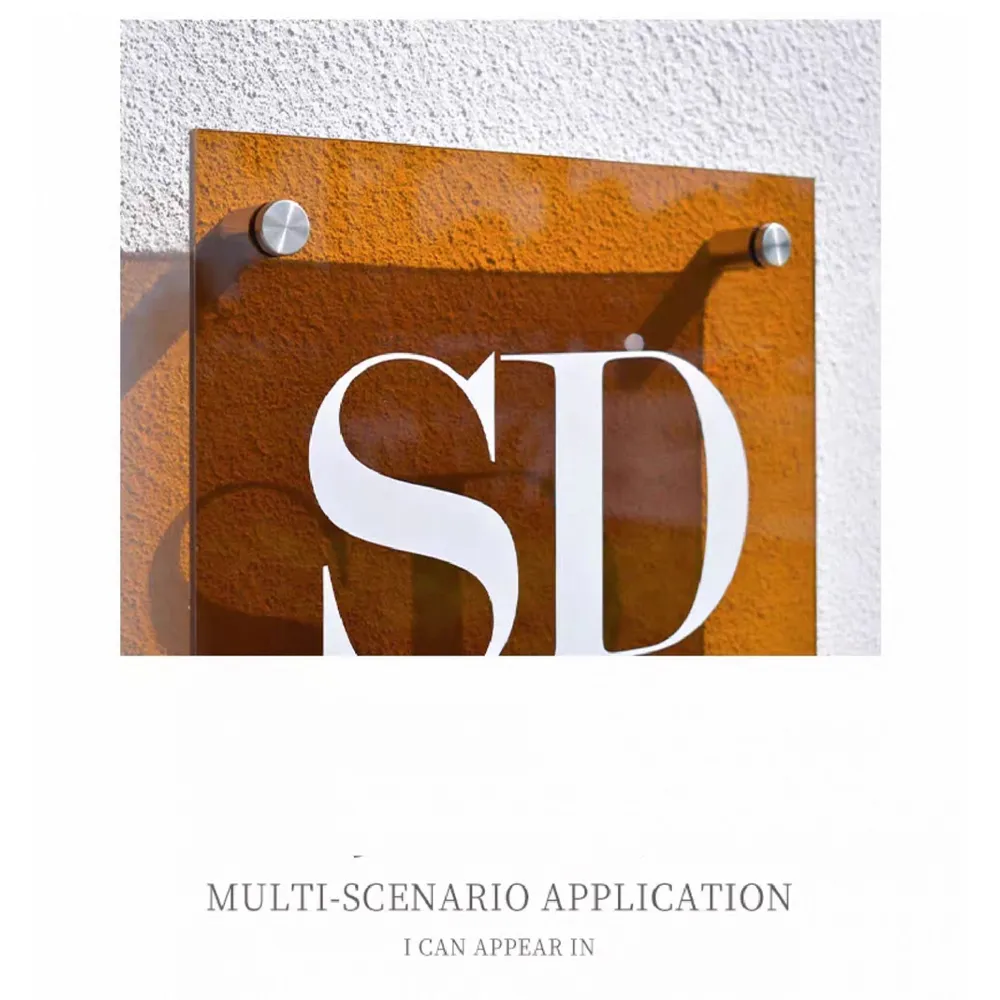

Customer DTF on acrylic case

Transparent acrylic sheet acrylic uv dtf back

Golden Use Cases for UV Direct Printing on Acrylic

- For Large Flat Acrylic Sheets and High-Volume Production

Used for mass production of acrylic panels where direct printing is faster than transfer.

Typical products: signage, exhibition boards, interior acrylic decoration.

Reason: A uv printer acrylic solution prints directly on flat boards with lower unit cost.

- For Ultra-Smooth Surfaces and High-Precision Details

When clients require sharp edges, clean text, and photo-level detail.

Typical products: control panels, premium branding, photorealistic prints.

Reason: UV direct printing produces the cleanest detail—ideal for a professional uv printer for acrylic setup.

- For Spot Gloss, Texture, and Embossing Effects

When projects require textures, spot varnish, or raised 3D layers.

Typical products: premium packaging, art replicas, custom acrylic parts.

Reason: Only a direct uv printer acrylic system can print varnish and embossed textures.

- For Oversized Acrylic Panels and Seamless Joint Printing

Used for very large acrylic panels requiring consistent colors and seamless assembly.

Typical products: wall art, mall installations, large lightboxes.

Reason: A professional uv printer for acrylic ensures precise alignment across panels.

Acrylic UV DTF & DTF on Acrylic Printing: Front and Back Technical Guide

DTF on Acrylic (Front Printing) DTF on Acrylic (Reverse Printing)

Backside Printing (View from Front | Recommended)

Printing Order: Color First → White Later

- Effet

Vibrant and Rich Colors

The design is protected by acrylic, making it scratch-resistant, wear-resistant, and fade-resistant.

High-end texture, suitable for brand logos, decorative paintings, and high-end displays.

Front printing (viewed from the front)

Printing order: White first → Colour second

- Effects

Colours lack transparency

Diminishes acrylic’s high transparency and glossy finish

Designs are exposed, resulting in lower durability

Recommendation: Generally not recommended unless specific technical requirements exist

Conclusion

UV direct printing on acrylic offers premium quality, strong adhesion, and texture effects.

UV DTF printing is faster, more flexible, and ideal for mass production.

If your business focuses on high-end acrylic products, a uv printer acrylic setup is the best choice.

If you need speed, versatility, and low-cost production across multiple materials, uv dtf printing provides the greatest flexibility—especially for an acrylic business UV DTF printer workflow.

FAQ

What methods are available for UV DTF on acrylic?

There are two methods for UV dtf on acrylic.

Direct printing onto acrylic sheets—suitable for flat acrylic sheets, offering straightforward operation and rich color saturation.

Printing onto crystal labels first, then affixing them to acrylic objects—ideal for irregularly shaped or finished acrylic items, providing greater flexibility.

Can transparent acrylic DTF on acrylic on both sides and viewed from the front?

Yes, this is also the most recommended approach.

By printing in reverse on the reverse side of the acrylic, the pattern appears when viewed from the front, with colors appearing more translucent and the texture more sophisticated.

What is the difference between front and back printing DTF on acrylic?

Front printing: White base followed by colour, resulting in less vibrant hues

This diminishes the acrylic’s inherent high transparency and brilliance

Back printing (recommended): Colour layer followed by white base

Colours appear more translucent with enhanced depth

The design is protected by the acrylic, offering superior scratch resistance, durability and fade resistance

Can acrylic sheets printed with DTF on acrylic undergo hot foil stamping?

Yes.

Following UV printing, secondary processes such as spot foil stamping may be applied. This technique is commonly employed for high-end signage and decorative finishes.

How long will the finished product with reverse-printed DTF on acrylic last?

The reverse-printed design is protected by the acrylic substrate itself:

Resistant to scratches

Resistant to fading

Longer service life

Highly suitable for long-term display and commercial applications.