UV DTF vs Traditional Sticker Printing: Key Differences

Stickers are everywhere. You see them on bottles, packaging, electronics, and gifts. Two popular printing methods stand out today: UV DTF and traditional sticker printing. Both create custom designs, but the results feel very different.

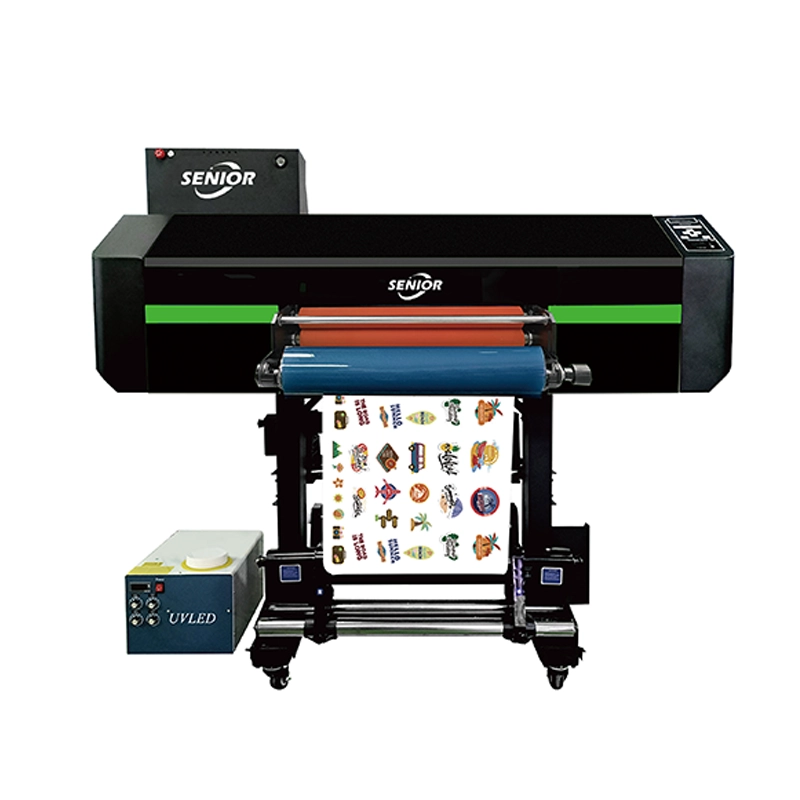

SE-620pro roll to roll UV DTF Printer

What is UV DTF Printer?

UV DTF printing uses UV ink and transfer film. The pattern prints on film, transfers onto the product. bold, glossy, and textured. It is also used for on glass, plastic, metal, and wood.

What is Traditional Sticker Printing?

Traditional sticker printing uses inkjet or laser printers with vinyl or paper sheets. The design goes directly onto the sticker. A clear layer often protects the surface. These stickers work well for simple labels and everyday packaging.

UV Printed Crystal Labels vs Screen Printing

| Item | Screen Printing | Crystal Label (Dome Label) |

|---|---|---|

| Process Principle | Uses a mesh screen template to directly print ink on the plastic surface | Prints the design first (via heat transfer or UV printing), then covers it with a clear resin or epoxy layer to create a 3D effect |

| Appearance | Flat, single or multiple colors, glossy but lacks depth | Distinct 3D effect and gloss; transparent layer adds a premium look |

| Durability | Ink sits on the surface, prone to wear, scratches, and fading over time | Resin layer protects the design; wear-resistant, scratch-proof, water-resistant, and weather-resistant |

| Applicable Materials | Commonly used on PP, ABS, PVC, PC plastics | Can be applied to plastics, metals, glass, and various other materials |

| Customization Flexibility | Suitable for simple designs, single or limited colors | Can print full-color, gradients, high-resolution designs; ideal for logos, QR codes, and detailed graphics |

| Texture / Feel | Flat surface, no thickness | Smooth and raised; noticeable tactile feel |

| Production Process | Requires creating a mesh screen; suitable for large-volume production | Can print or mold directly; ideal for small to medium volumes and high-precision customization |

UV Direct Printing vs Crystal Labels vs Screen Printing on Plastic

Screen Printing on plastic

Crystal Label on plastic

UV Direct Printing on Plastic

UV DTF vs Traditional Sticker Printing

UV DTF gives a 3D feel. Traditional stickers stay flat.

UV DTF sticks to curved or uneven surfaces. Traditional stickers prefer flat surfaces.

UV DTF can resists water, UV light, and scratches. Traditional stickers will can fade or peel.

UV DTF looks premium and professional. Traditional stickers look basic and smooth.

Which Printing Method Should You Choose?

It depends on your needs. For budget projects, traditional stickers are fine. For premium products, UV DTF is better. If you want durability and a luxury look, UV DTF wins.

Why UV DTF is Becoming More Popular

Brands want labels that last. Sellers want designs that stand out. UV DTF delivers both. It has strong adhesion, vibrant color, and a modern finish. so that is why why UV DTF keeps growing in popularity.

Conclusion

Both UV DTF and traditional sticker printing serve a purpose. Traditional printing is cost-friendly and fast. UV DTF offers strength, quality, and flexibility. As demand shifts toward premium custom printing, UV DTF is leading the way.