With the growing demand for customization, short-run production, and high-value printing, the uv inkjet printer has become widely adopted across multiple industries.

This article explains how UV inkjet printers work, their advantages, applications, and how to choose the right model for your business.

What Is a UV Inkjet Printer?

A UV inkjet printer is a digital printing device that uses UV-curable ink.

The ink is jetted onto the surface and instantly cured by UV light, creating sharp and durable images.

Its key feature is instant curing, eliminating drying time and improving efficiency.

UV Inkjet Printing vs Solvent Printing

Solvent ink penetrates the material surface, offering excellent outdoor durability.

It is commonly used for billboards, vehicle wraps, and roll media printing, but requires proper ventilation and environmental control.

UV Inkjet Printing – A More Flexible Digital Manufacturing Method

UV ink cures on the surface, forming a solid layer that adheres to various materials.

UV printing is ideal for short runs, customization, and fast delivery.

For non-porous materials like glass or metal, proper surface pretreatment is essential.

How UV Inkjet Printing Improves Production Efficiency

Thanks to instant curing, UV inkjet printing allows immediate post-processing.

This reduces production time and helps businesses respond quickly to urgent orders.

Versatility: Material Compatibility of UV Inkjet Printers

UV inkjet printers can print on paper, metal, acrylic, leather, and wood.

A uv flatbed inkjet printer enables direct printing on rigid boards and finished products, expanding application possibilities.

Diatomaceous earth mat Acrylic badges Imitation embroidery

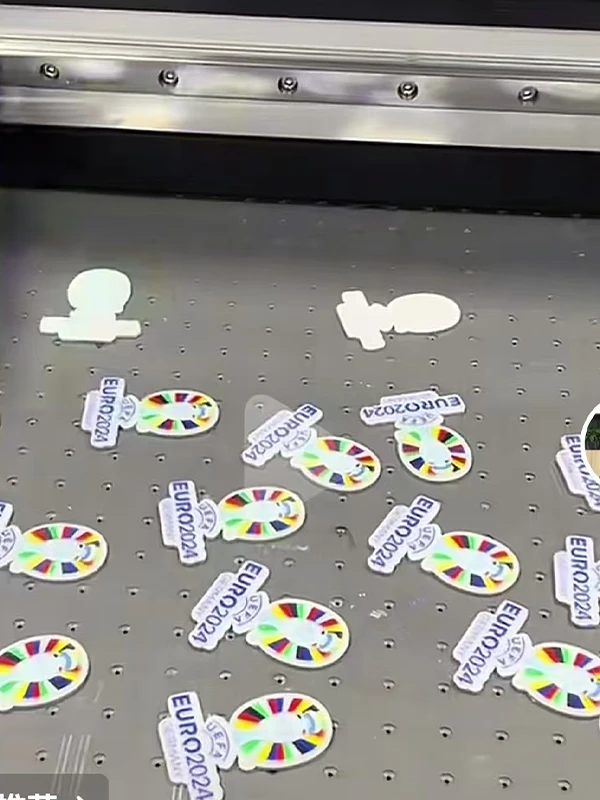

Printable Materials and Shapes

As long as the surface is stable and properly treated, UV printing is possible.

Adjustable printhead height allows printing on materials with varying thicknesses and shapes.

Key Technical Configurations for UV Inkjet Printing

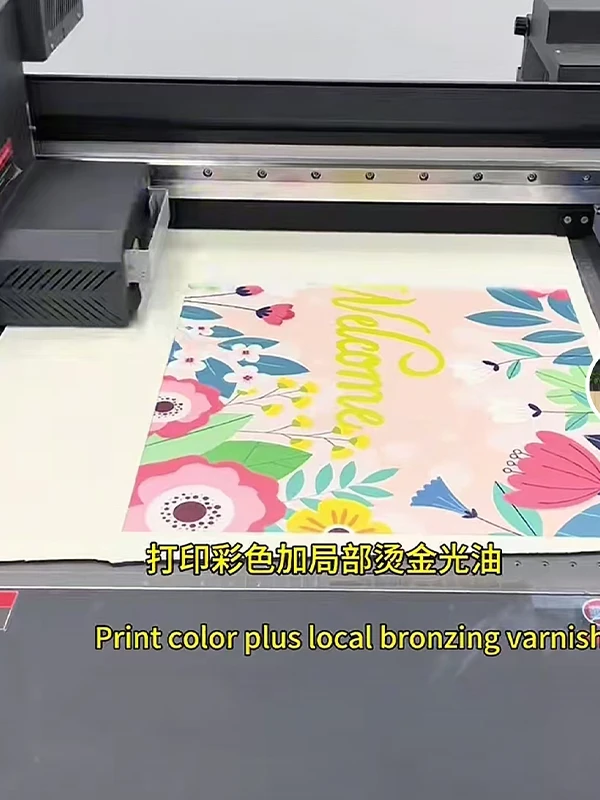

UV printing systems often include white ink circulation, varnish layers, and RIP software.

The quality of uv ink for inkjet printer directly affects color vibrancy, adhesion, and durability.

Typical Applications of UV Inkjet Printers

UV inkjet printers are widely used for signage, decorative panels, customized gifts, and industrial marking.

Multi-layer printing enables 2.5D textured effects for premium products.

Main Equipment Types Offered by UV Inkjet Printer Manufacturers

Leading uv inkjet printer manufacturers offer several machine types, including:

- UV flatbed printers

- Roll-to-roll UV printers

- Hybrid UV printers

- Specialized printers for curved or irregular objects

How to Choose the Right UV Inkjet Printer?

When choosing a UV inkjet printer, consider product size, material type, production volume, and special effect requirements.

A clear application focus ensures maximum return on investment.

Summary of UV Inkjet Printer Advantages

UV inkjet printers offer fast production, material versatility, and high-value output.

They are an ideal solution for businesses seeking efficiency, flexibility, and customization.