In the leather goods industry, surface decoration techniques directly determine a product’s grade, added value, and market competitiveness. Common leather surface treatments include embossing, uv stamping, and the rapidly developing UV leather printing.

So, what exactly distinguishes these techniques? Which one is better suited for today’s small-batch, customized market? This article will compare and analyze them from multiple perspectives, including process principles, effects, costs, and application scenarios.

Comparison of Process Principles

UV Leather Printing

UV printer leather is a digital direct-to-surface process that uses printer UV leather to apply specialized UV inks directly onto leather surfaces. These inks are instantly cured and set during printing via UV light exposure.

Core Features:

No plates or molds required

Supports full-color CMYK + white ink + varnish

Enables localized embossing and tactile 3D effects

Suitable for genuine leather, PU leather, microfiber, and various other materials.

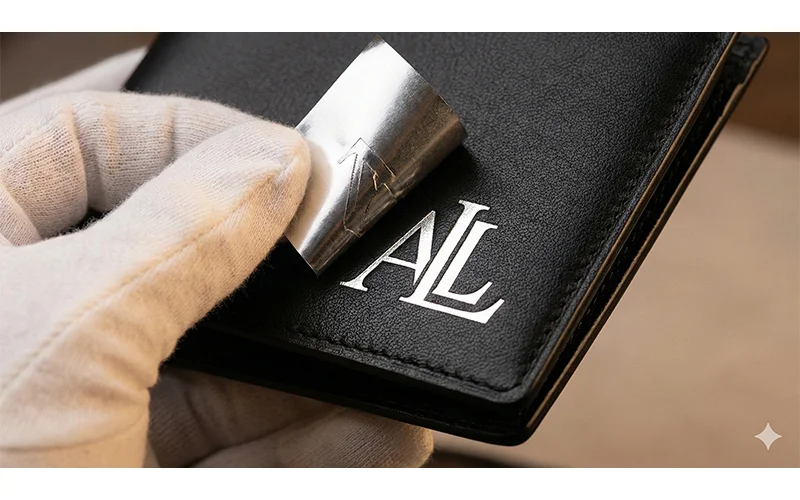

Leather Embossing Process

Leather embossing is a traditional surface decoration technique that uses metal dies to press patterns directly into the leather surface under external force or high temperature and pressure, creating clear, lasting raised and recessed textures. It is commonly used on leather goods, footwear, wallets, and brand logos.

Common Embossing Methods

- G-Clamp Embossing

Pre-fabricate a copper die. Place a hard backing board beneath the leather, position the die, and slowly apply pressure using a G-clamp. Within seconds, a deep, textured embossed pattern emerges. Ideal for small-batch, handcrafted customization.

- Copper Die Hammer Embossing

Attach a small copper die (e.g., name, logo) to a handle. Align it with the leather and strike vertically with a hammer to complete the embossing. This rapid method suits small patterns and single-item production.

- Core Characteristics

Requires pre-made specialized dies

Strong three-dimensional texture with consistent results

Fixed patterns, difficult to modify

Better suited for traditional, high-volume, or uniform-style production

uv stamps for leather

UV stamps are a premium decorative technique that combines UV stamp asme with traditional hot stamping. It preserves the metallic luster of hot stamping while significantly enhancing design flexibility and detail expression.

- Process Flow

Print colorful patterns onto leather surfaces using a stampa UV DTF machine (such as the UV6090).

Precise printing of UV ink stamp varnish onto designated areas.

After printing, a UV lamp for stamps machine applies heat and pressure to transfer gold or silver foil onto the varnished areas.

Removing the backing film reveals a rich, luminous metallic effect.

- Process Effects & Advantages

- Rich, three-dimensional gold/silver foil stamping with brilliant metallic luster

- Scratch and abrasion resistant, ideal for high-use leather goods

- Supports high-precision micro-printing: 1 mm lines and 0. x mm fonts remain crisp and legible

- Enables localized foil stamping seamlessly integrated with color patterns

- Eliminates traditional foil stamping plates for flexible design modifications

Visual Effects vs. Design Flexibility

| Comparison Dimension | UV Printing | Embossing | Hot Foil Stamping |

|---|---|---|---|

| Color Performance | Full color, high saturation | No color variation | Single color / metallic |

| Gradient Capability | Supported | Not supported | Not supported |

| Tactile / 3D Effect | Raised texture achievable with layered white ink | Strong embossed texture | Strong raised texture |

| Detailed Precision | Very high | Limited by embossing mold | Medium |

| Personalization Capability | Excellent for customization | Almost no customization | Limited customization |

Conclusion

UV leather printing offers distinct advantages for complex patterns, gradient colors, and personalized designs, while embossing is better suited for traditional, fixed-style products.

Production Costs vs Efficiency

uv leather printing

Initial Investment: Equipment only, no mold costs

Per-Unit Cost: Low, ideal for small batches

Prototyping Speed: Instant printing

Perfect for custom orders and fast turnaround

Embossing & uv stamps

High upfront costs (dies / foil stamping machines)

High costs for small batches

Design modifications require new plates

More suitable for long-term, high-volume production

Application Scenario Comparison

UV leather printing Applications

Direct-to-Leather Printing for Shoe Uppers

Personalized Customization for Bags and Wallets

Custom Leather Labels and Logos

Premium Gifts and Cultural & Creative Products

Rapid Production of Small Batches and Multiple Styles

Embossing & Foil Stamping Applications

Luxury Brand Logos

Traditional Brand Identities

Mass-Produced Uniform-Style Products

Environmental Friendliness and Material Adaptability

UV printer leather: Ink cures instantly upon application, resulting in low VOC emissions and greater environmental sustainability.

Embossing/Hot Stamping: Involves high temperatures, pressure, and consumables, leading to relatively higher energy consumption.

Additionally, leather uv printing machine offers superior adaptability to leather thickness and shape, making it particularly suitable for irregular and flexible leather goods.

Which process is better suited for the future market?

As the market shifts from mass production of identical items to small-batch customization, leather business UV DTF printers are becoming the preferred solution for an increasing number of leather processing plants, shoe factories, and custom workshops:

Greater design freedom

Faster delivery

Lower inventory pressure

Easier to create differentiated products

Conclusion

If you seek:

Rapid prototyping

Personalized customization

Full-color visual effects

Low minimum order quantities

UV printer news today offers a more competitive solution.

However, for:

Long-term, stable mass production

Consistent brand logos

Traditional craftsmanship aesthetics

Embossing and foil stamping retain their irreplaceable value.