Metal Etching Enters the Plate-Free Era: UV Printing on metal Enables Simpler, More Precise Metal Etching Processes.

In the processing of metal jewelry, metal cards, stainless steel nameplates, aluminum plate signs, and similar applications, traditional etching processes often involve cumbersome workflows requiring film production, screen printing, development, and multiple calibration steps. Today, with advancements in UV Printer technology, a new industry trend is emerging: a plate-free, precision-positioning, high-resolution UV Printing on metal etching solution.

This article will explore:

Why is metal etching becoming increasingly simple? How do UV Printer replace traditional plate-making? And how do they achieve integrated etching and precise color filling?

Pain Points of Traditional UV Printing on metal Etching

The conventional metal etching process typically involves:

- Film production

- Plate making and exposure

- Screen printing of resist blue oil

- Manual alignment

- Lengthy etching process

The issues are: - High plate-making costs

- Complex, time-consuming workflow

- Precision affected by manual handling and screen quality

- Difficulty processing small fonts

- Prone to misalignment in multi-color resist application

As demand for small-batch, diverse customization grows, these problems become increasingly apparent.

UV Printing on metal Etching Process

No Plate Making Required—Print and Etch Simultaneously

Using a UV Flatbed Printer 6090 + specialized UV etching ink (corrosion-resistant blue ink), you can rapidly complete tasks that previously required multiple steps.

1)Directly Print Corrosion-Resistant Blue Ink (Acid-Resistant, Not Alkali-Resistant)

Use a UV Flatbed Printer 6090 to directly print “corrosion-resistant blue ink” onto metal surfaces like stainless steel or aluminum plates:

- No coating required

- No screen printing needed

- No plate making, developing, or exposure required

- Proceed directly to etching after printing

The printed corrosion-resistant blue ink resists acids but not alkalis, perfectly matching standard etching processes: - Acid etches metal → Blue ink protects patterned areas

- Alkaline solution removes ink → Etching complete

2) High Precision: Supports 1mm small fonts and circuit-level details

6090 Flatbed UV Printer achieve 1200 DPI resolution, clearly rendering text or lines as small as 1–2 mm. Ideal for:

- Micro-text nameplates

- Fine line patterns on metal cards

- Detailed icon outlines

- Precise etched circuit traces

3) No need to replace the printhead—just change the ink.

Standard 6090 flatbed uv printer can be used by:

Switching to etching-specific ink

Using metal etching-related ICC profiles and cleaning procedures

You can start UV Printing on metal etching processing without purchasing new equipment.

Visual Positioning for Color Filling

After etching is completed, color filling or oil dripping is often required. Traditional oil dripping requires molds or fixtures for positioning, which is extremely time-consuming.

Now, this can be achieved simply using the visual positioning system of a UV Printer for metal.

- Automatic alignment, no fixtures or jigs required

Camera identifies positioning points → Automatically calculates position → Precise ink application

Achieves:

- No misalignment

- No ghosting

- No color bleeding

2. Precision Color Filling (1200 DPI)

Accurately fills colors into etched grooves with sharp edges and no color bleeding.

3.Supports Multi-Color Drip Effects

UV printers can directly simulate traditional drip techniques:

- Multi-color

- Multi-layer thickness

- More uniform

- Faster

Offers greater flexibility and labor savings compared to traditional dripping.

Traditional Etching vs UV Etching

| Feature | UV Etching Printing | Traditional Etching |

|---|---|---|

| Plate Making Required | No | Requires film and screen preparation |

| Cost | Low | High |

| Precision | Up to 1200 DPI, supports 1 mm text | Depends on manual operation and screen quality |

| Process Flow | Printing → Etching → Color Filling | Plate Making → Exposure → Screen Printing → Etching |

| Positioning Accuracy | Automatic visual positioning | Manual alignment, prone to errors |

| Small-Batch Customization | Highly flexible and efficient | High cost, low flexibility |

| Doming Effect | Direct multi-color UV doming printing | Requires manual work or molds |

UV Printing Metal Etching Technology

Direct UV Printer: Utilizing specialized high-adhesion UV inks (such as UV inks formulated for treated metals), the ink is directly jetted onto pretreated metal surfaces and instantly cured by UV lamps. This process resembles “printing” or “coating.”

· UV Mask Etching: This technique more closely resembles traditional “etching.”

· First, a pattern is printed onto a photosensitive ink (or resist film) coating the metal surface using a UV Flatbed Printer 6090.

· The pattern is then exposed to UV light and developed, exposing the areas to be etched.

· Finally, chemical etching (acid/alkali) or physical etching (laser) is applied to the exposed areas, creating raised or recessed textures. Here, the 6090 Flatbed UV Printer serves to create a precise resist mask.

Applicable Industries

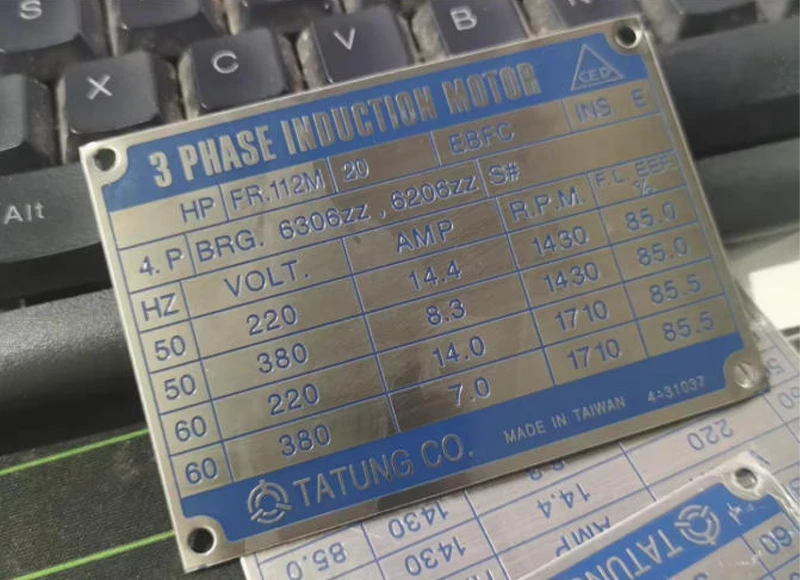

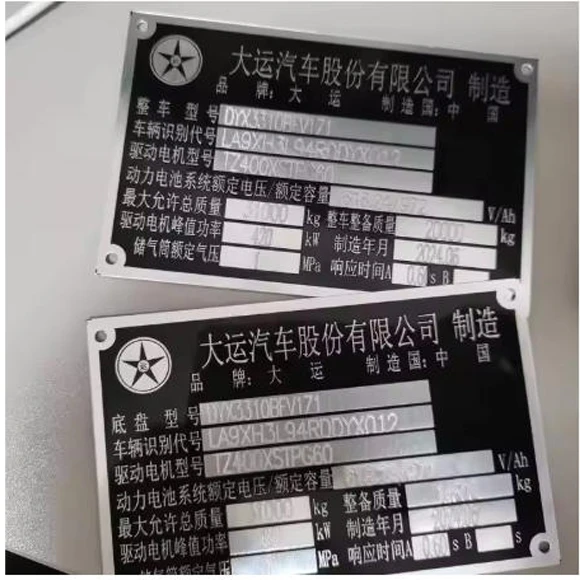

Metal Nameplates

Stainless Steel Nameplates

Aluminum Nameplates

Metal Ornaments

Metal Crafts

Metal Membership Cards, Metal Business Cards

Housing Nameplates, Industrial Labels

Wherever “etching + color filling” is required, UV Printing on metal technology can handle nearly all applications.

UV Printing Metal Etching Technology: Future Trends

Metal etching is evolving from “heavy processes and multiple steps” toward “plate-free, digital, and high-precision” methods.

What is UV Printing on metal combined with vision-based positioning simplify the entire workflow, enhancing efficiency and making it ideal for small-batch customization and personalized demands.

Moving forward, traditional screen printing and plate-making will gradually be replaced, with UV etching printing emerging as the mainstream choice in the metal processing industry.