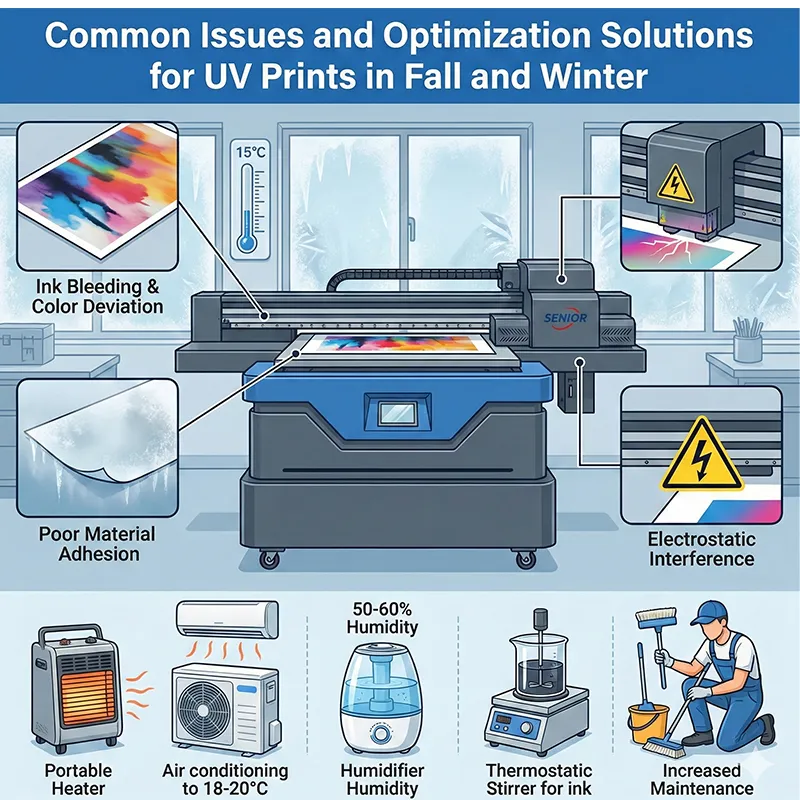

As the weather gradually turns colder, production workshops using UV prints during autumn and winter often encounter specific issues such as ink bleeding, color bleeding, and color deviation.

Often, printhead tests show normal results, yet actual print quality remains unsatisfactory. This does not necessarily indicate equipment malfunction but is influenced by environmental temperature, humidity, and ink condition. This article systematically analyzes common UV prints problems in autumn and winter and provides optimization solutions.

Low ambient temperatures reduce ink flowability

Issue

Minor nozzle clogging, stringing, and ink splatter occur during uv digital printer.

Ink flow is restricted, resulting in unstable print quality.

Cause Analysis

When workshop temperatures drop below 18°C during autumn and winter, UV ink viscosity increases. This reduces ink flow from the printhead, causing flat UV printer abnormalities.

Solution

Before starting the cheapest uv printer, preheat the workshop using air conditioning to raise the temperature above 18–20°C.

Maintain a stable temperature throughout the production environment to minimize the impact of temperature fluctuations on ink performance.

Affordable uv printer Ink Viscosity Changes Cause Color Deviation and Ink Breakage

Issue

UV printer for sale color deviation

Ink breakage and ink drifting occur during printing

Cause Analysis

In low-temperature environments, home UV printer ink becomes thicker, resembling syrup, and its flowability decreases, leading to an uneven ink supply to the printhead.

Solution

Use a thermostatic stirrer to maintain stable ink temperature and viscosity.

Test ink viscosity before used uv printer to ensure uniform ink flow.

Heat ink appropriately when necessary to improve fluidity.

6090 uv printer Material Adhesion Decreases Due to Low Temperature

Issue

Poor adhesion of 6090 UV printer ink

Surface prone to ink splatter and peeling

Cause Analysis

Sheets, glass, or other materials brought directly from the warehouse to the large uv printer workshop carry cold air on their surfaces, resulting in poor ink adhesion.

Solution

Place materials in a warm, air-conditioned workshop in advance to allow their temperature to match the workshop environment.

Ensure material surfaces are dry and at an appropriate temperature before proceeding with the UV printer for small business.

Used uv printer Workshop Air Dryness Causes Electrostatic Interference

Issue

Used UV Printer Ink Splatter

Unstable Print Quality

Cause Analysis

During autumn and winter, dry air causes static electricity to accumulate, interfering with inkjet nozzles and affecting UV sticker printer quality.

Solutions

Humidity in the uv printed pins workshop is maintained between 50% and 60%.

Humidifiers and static eliminators are used to ensure environmental humidity and static safety.

Temperature and humidity are measured regularly to maintain a stable workshop environment.

Insufficient UV DTF Sticker Printer Maintenance Frequency

Issue

Nozzle clogging or uneven ink flow

Unstable UV DTF Sticker Printer results

Cause Analysis

Winter reduces ink fluidity, requiring more frequent machine maintenance.

Solutions

Increase nozzle cleaning and maintenance frequency

Perform standard cleaning procedures daily before closing

Regularly inspect ink pathways and nozzles to ensure smooth ink flow

Low Temperature Impact on Ink Curing in uv dtf custom printing Workshop

Issue

Incomplete ink curing, prone to scratching

Unstable rotary uv printer speed and precision

Cause Analysis

In low-temperature environments, UV ink curing speed decreases, affecting print uv 2025 results.

Solution

Increase UV lamp power

Appropriately reduce printing speed

Ensure complete ink curing to improve uv sticker printer quality

Summary and Recommendations

Most issues with the UV prints during autumn and winter are not caused by equipment malfunctions but rather by environmental factors and daily operational practices.

The following measures can significantly improve printing stability and quality:

- Maintain workshop temperature above 18–20°C

- Keep workshop humidity at 50%–60%

- Use a thermostatic stirrer to maintain ink fluidity

- Pre-adjust material temperature

- Increase printhead cleaning and machine maintenance frequency

- Adjust UV lamp power and print speed to ensure ink curing

By mastering these methods, you can reliably operate the UV prints during autumn and winter, achieving high-quality, high-efficiency printing production.